CNC Integration in Precision Universal Tool Grinders: Enhancing Productivity

The Role of CNC Technology in Precision Universal Tool Grinders

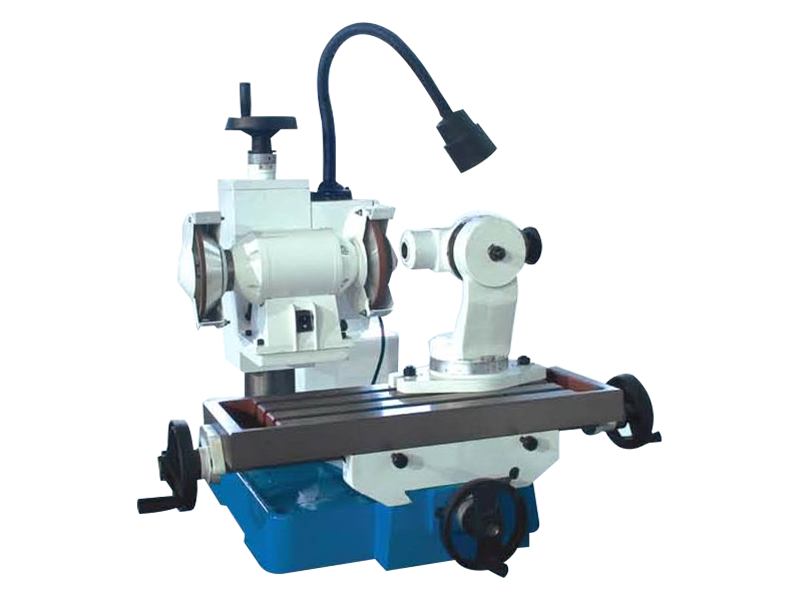

CNC integration in Precision Universal Tool Grinders enables automation, which is one of the key factors driving the efficiency and productivity of modern manufacturing systems. With CNC, operators can program complex grinding operations, automate repetitive tasks, and achieve higher accuracy levels compared to traditional manual grinding methods. The ability to set precise parameters and adjust grinding tools for external cylindrical grinding, internal cylindrical grinding, and flat grinding leads to increased throughput and reduced manual intervention.

This adaptability is particularly valuable in environments where precision is critical. CNC systems allow operators to fine-tune settings for various tool types and sizes, ensuring that the grinding process meets specific requirements while minimizing human error. In the competitive landscape of tool and mold manufacturing, this technological advancement allows companies to meet demanding production schedules and stringent quality standards with greater ease.

Jiangsu Dingshun Heavy Duty Machine Tool Co., Ltd.: A Leader in CNC Grinding Machines

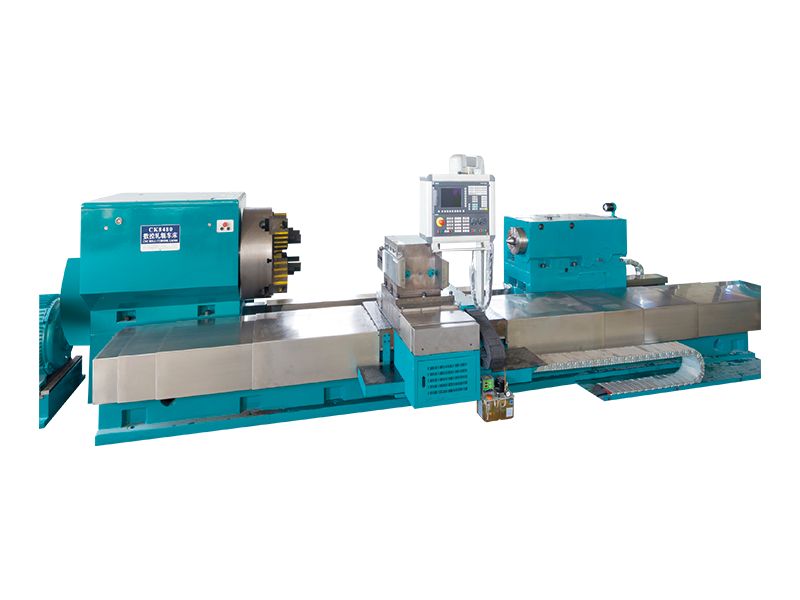

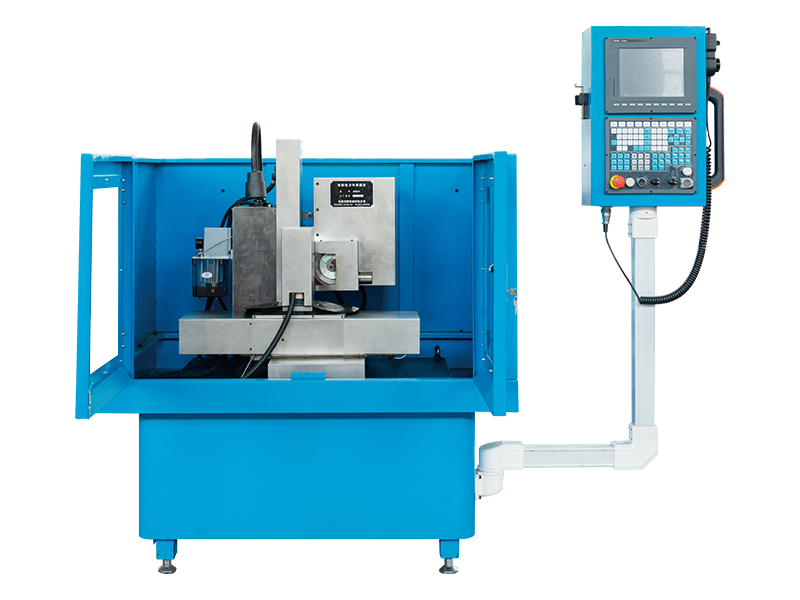

Jiangsu Dingshun Heavy Duty Machine Tool Co., Ltd. (formerly Nantong Baoshun Machinery Co., Ltd.) has long been at the forefront of providing advanced machine tools for various industries, including steel production and metallurgical sectors. Since its establishment in 2002, the company has specialized in producing high-precision CNC machine tools, including the ZWM150 Precision Universal Grinding Machine. Their extensive expertise in CNC technologies positions them as leaders in the field, ensuring that each product, from CNC roll lathes to CNC grinding machines, integrates cutting-edge technology to enhance productivity.

The company's product range includes various CNC machines designed for specific grinding applications. Their CNC roll crescent groove processing machines and CNC roll ring grinders are designed to optimize grinding processes, increasing efficiency and improving the quality of finished products. This commitment to innovation and technological advancement has allowed Jiangsu Dingshun to become a well-known brand in the domestic steel and metallurgical industries, further underscoring the importance of CNC integration in achieving operational excellence.

How CNC Integration Boosts Performance and Flexibility

CNC systems in Precision Universal Tool Grinders provide several advantages that help improve productivity. The ease of programming allows operators to quickly switch between different grinding tasks, making the grinder adaptable to a variety of tool types and manufacturing needs. This flexibility enables manufacturers to process a wide range of components without the need for manual adjustments, reducing downtime and improving the overall efficiency of production lines.

Moreover, the integration of a CNC system enhances the consistency of machining results. CNC-controlled grinding machines can reproduce the same grinding process with remarkable accuracy, ensuring that the finished products meet strict tolerance requirements. For industries that rely on precise tool shapes and sharp cutting edges, such as mold manufacturing, this consistency is crucial for maintaining product quality over time.

Real-Time Feedback and Monitoring for Better Control

One of the standout features of CNC integration in Precision Universal Tool Grinders is the digital display function, which provides real-time feedback on the machining status. Operators can monitor the entire grinding process, adjusting parameters if necessary to optimize performance. This ability to continuously monitor and control the grinding process helps minimize errors and improve overall production efficiency.

For companies like Jiangsu Dingshun, which specializes in supplying CNC machine tools, this feedback mechanism is a key component of their quality assurance system. With real-time data, manufacturers can identify issues early on, allowing for quick intervention before any significant problems arise. This level of precision control enhances the reliability of the grinding process, making CNC-integrated Precision Universal Tool Grinders indispensable in industries demanding high standards of performance.

The Future of Tool Grinding with CNC Technology

Looking ahead, the future of tool grinding lies in the continued integration of advanced CNC technologies. Companies like Jiangsu Dingshun are constantly innovating, seeking new ways to enhance the capabilities of CNC machines to meet the evolving needs of industries worldwide. With their commitment to quality, the company is well-positioned to support the growth of the metallurgical and manufacturing sectors, helping clients stay competitive in an increasingly demanding global market.

The precision, efficiency, and adaptability offered by CNC-integrated Precision Universal Tool Grinders will continue to drive advancements in tool production technology. As the demand for higher quality, faster production times, and greater flexibility in manufacturing grows, the role of CNC machines in optimizing productivity will only become more significant. For companies involved in tool and mold manufacturing, embracing CNC integration is no longer optional—it's a necessary step toward achieving sustained success in a highly competitive industry.

English

English  русский

русский  Español

Español  عربى

عربى

View More

View More View More

View More