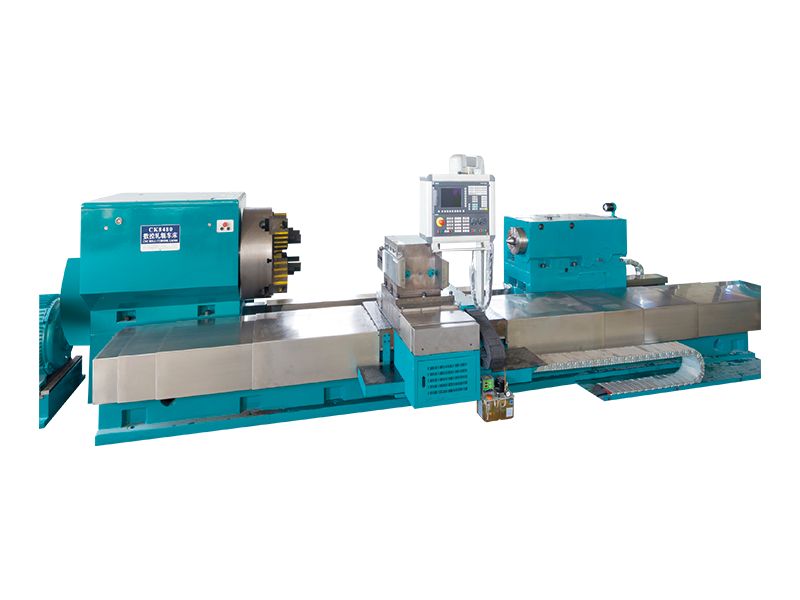

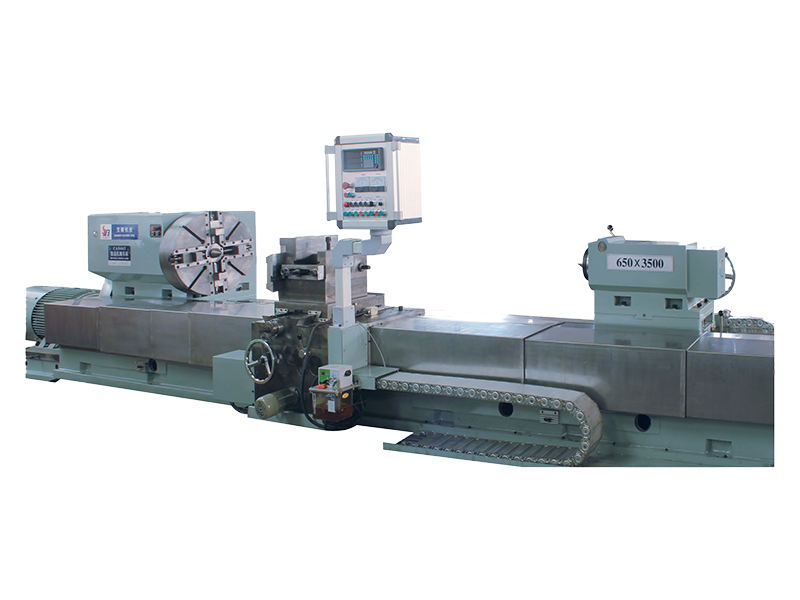

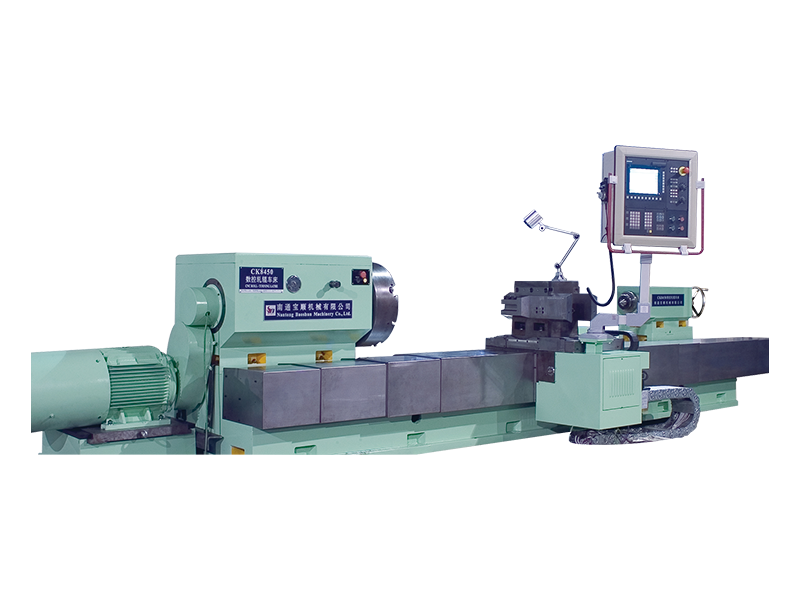

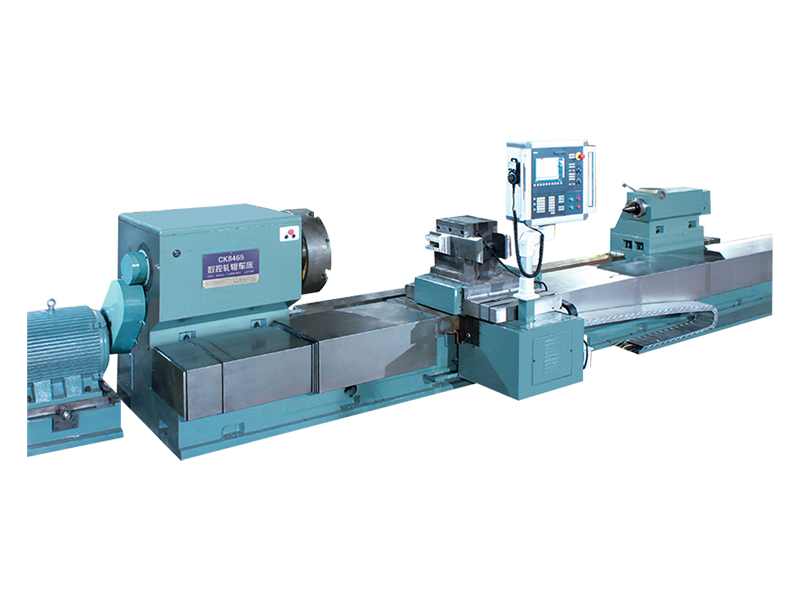

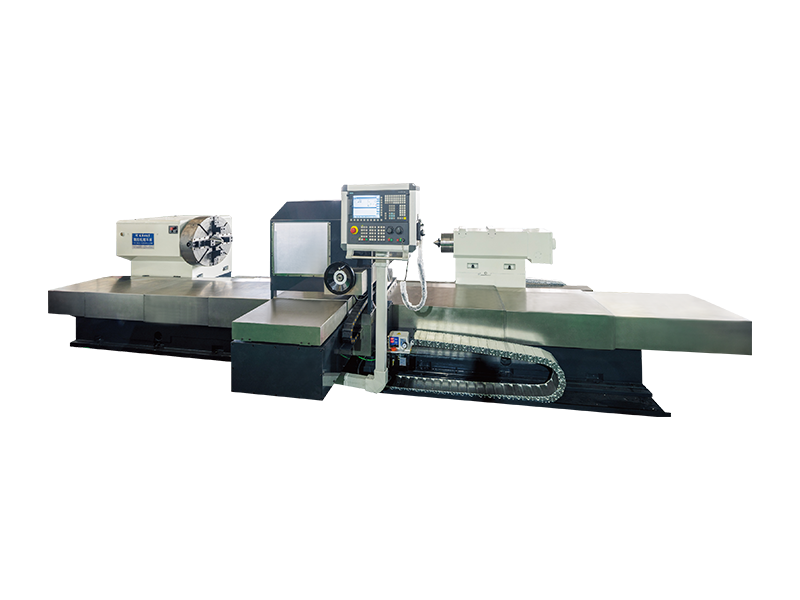

Jiangsu Dingshun Heavy Duty Machine Tool Co., Ltd. (Nantong Baoshun Machinery Co., Ltd.) was established in 2002. It is an enterprise that has long been engaged in providing machine tool equipment for the metallurgical industry and steel enterprises. CNC Tool Grinding Machine Suppliers in China. It has a deep foundation and rich experience in specialized machine tool equipment and is a supplier of solutions for steel enterprises. It is also a qualified supplier for the Shanghai 704 Research Institute of China Shipbuilding Industry Corporation, undertaking important scientific research projects such as torque sensors and other professional components. The company specializes in producing XK500 series CNC roll crescent groove processing machine tools, CK84 series CNC roll lathes, CA84 series digital display roll lathes, CNC roll ring lathes CK450, CXK9550 CNC turning and milling composite machine tools, CXK9580 patterned plate CNC turning and milling center, CNC diamond grinding wheel repair machine DK060, CNC vertical roll ring grinder MK630, CNC roll ring grinder MK001-5, CNC grinding machine ZKM150, ZWM150 precision universal grinding machine and other related supporting products. We are CNC Tool Grinder Manufacturers.

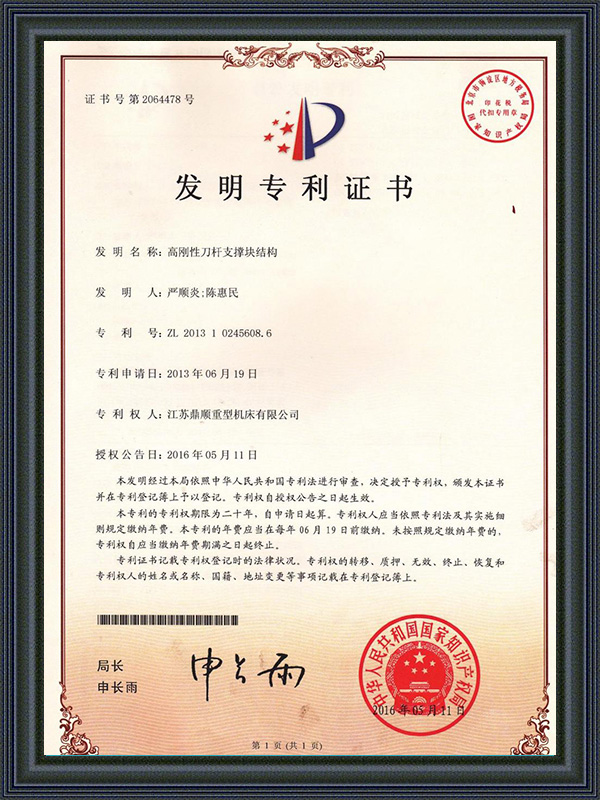

The company has several large pieces of equipment provided by domestic and foreign brand enterprises, ensuring the quality of the produced machine tools and timely delivery. Over the years, with strong technical strength, mature products, and a comprehensive service system, our products have been sold to major steel companies across the country and foreign markets. Our customers have responded positively and we have obtained multiple national patents and independent intellectual property rights. Our company has now become a well-known brand enterprise in the domestic steel enterprise and metallurgical design institute roll processing machine tool industry.

The company will fully leverage its advantages, adhere to the purpose of "technological innovation, serving the market, treating people with integrity, and pursuing quality", and the corporate philosophy that products are the character. It will continuously innovate in technology, equipment, service, and management methods to continue developing more metallurgical industry products that meet future development needs and promote the development of China's steel industry. Custom CNC Tool And Cutter Grinder Factory. At the same time, we will also rely on our own technological and financial strength to actively engage in industry-university research cooperation with domestic and foreign peers, universities, research institutes, and other research projects.

|

Main specifications and technical parameters |

|

|

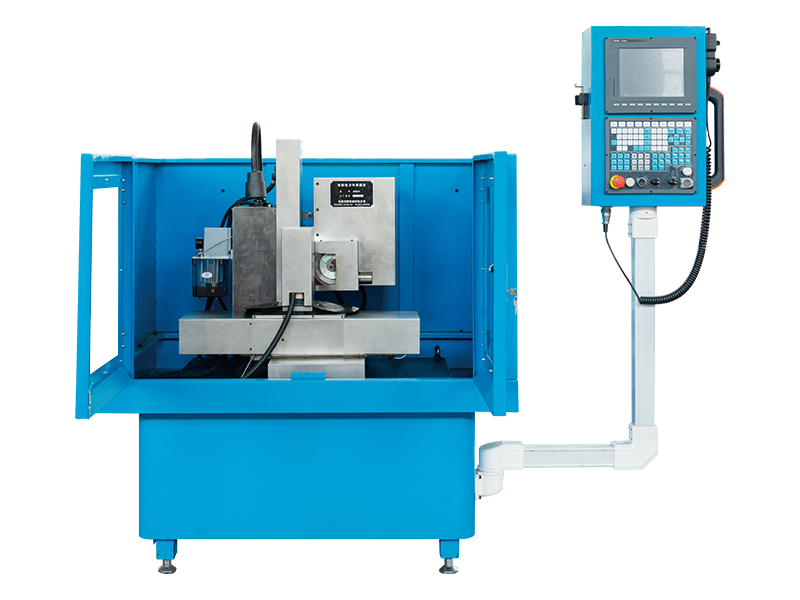

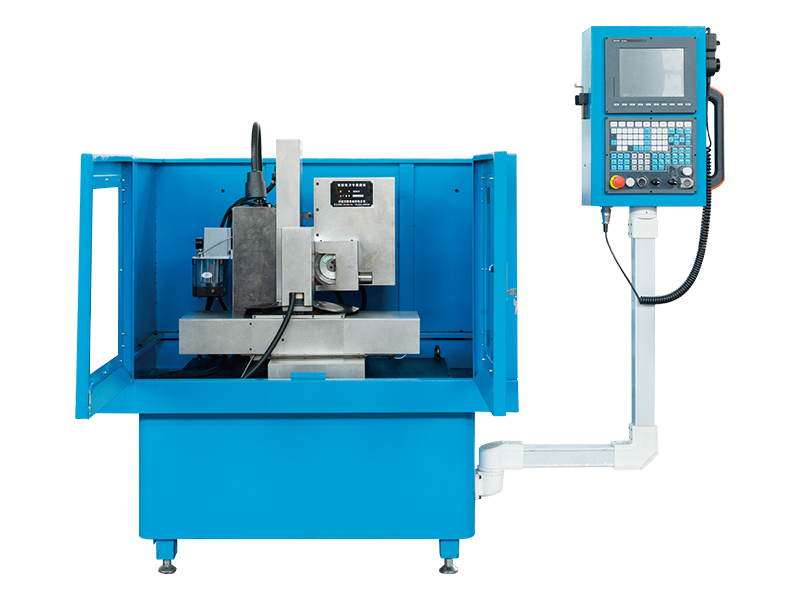

ZKM150 High-Speed and High-Efficiency CNC Milling Cutter/Bar Cutter Special Grinder |

|

|

Machining thread milling cutter diameter range |

Φ2.5-Φ10mm |

|

Thread milling cutter specification range |

10 snails. -50 snails |

|

Standard for thread milling cutter |

National standard, Japanese standard, British standard, American standard |

|

Position detection |

Probe contact |

|

Cooling mode |

Air cooling |

|

Spindle grinding wheel |

Superfine particle |

|

Grinding wheel spindle motor power |

750W |

|

Spindle speed |

2800r/min |

|

Equipment power |

4.5kw |

|

Maximum line speed of the grinding wheel |

32m/s |

|

X-axis ball screw direct drive |

Stroke 260mm position control resolution 0.001mm |

|

Y-axis ball screw direct drive |

Stroke 100mm position control resolution 0.001mm |

|

Z-axis ball screw direct drive |

Stroke 150mm position control resolution 0.001mm |

|

A-axis precision gear reduction rotary drive |

Stroke -45º~45º position control resolution 0.001º |

|

C-axis precision gear reduction rotary transmission |

Stroke -20º~20º position control resolution 0.001º |

|

Minimum data unit |

0.001mm(or 0.001 degrees) |

|

Maximum data size |

±9999.999mm |

|

Number of control axes |

Five axes, |

|

Machine power supply |

380v/220v |

|

Machine size (L × W × H) |

1200*1000*1300 |

|

Machine weight |

350kg |

|

CNC marking rod cutter special grinding machine KM150-A |

|

|

Machining tool diameter range |

φ6-φ12 mm |

|

Machining tool length range |

45~100 mm |

|

Maximum cutting tool length |

20 mm |

|

Machine power supply |

380v |

|

Machine power |

1.1kw |

|

Machine size (L × W × H) |

1250*1000*1300 |

|

Machine weight |

350kg |

English

English  русский

русский  Español

Español  عربى

عربى

View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >> View More >>

View More >>