How CNC Grinding Machines Achieve Complex Geometries for Precision Manufacturing

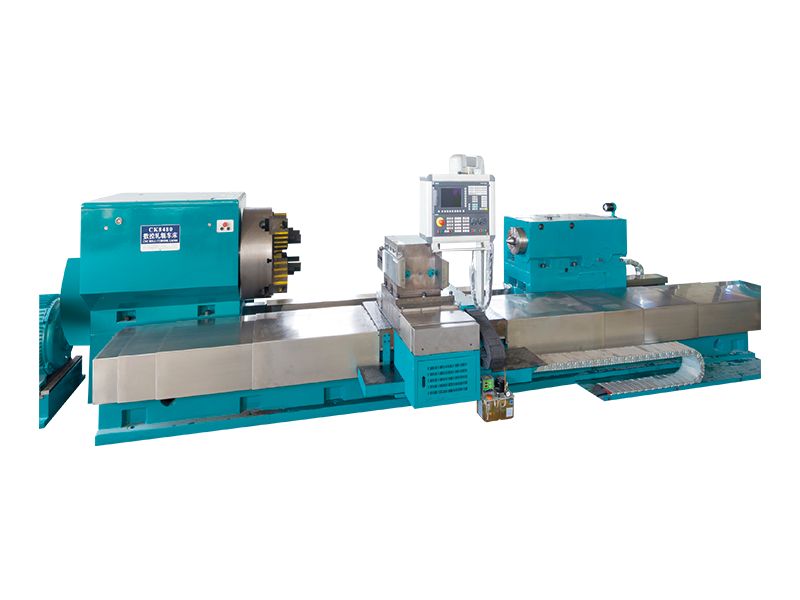

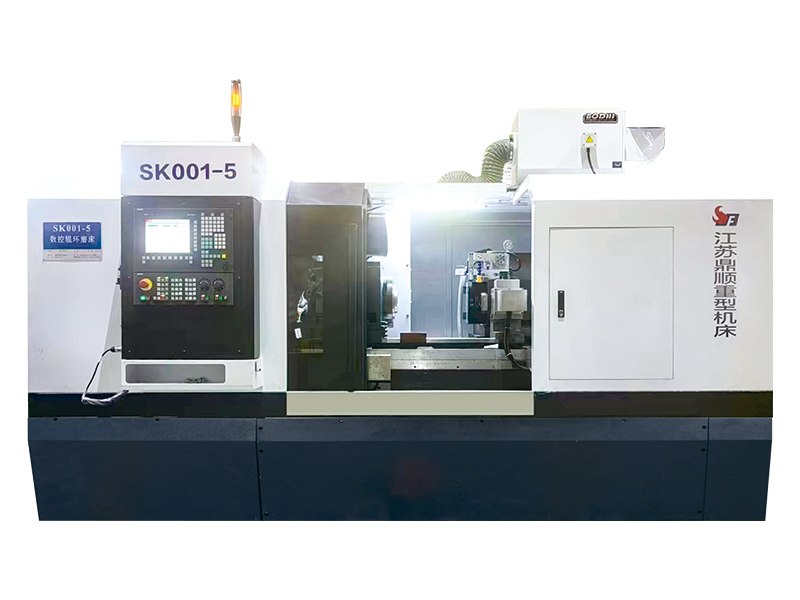

CNC grinding machines have revolutionized the world of precision manufacturing by enabling the production of complex geometries that were once considered impossible with traditional machining methods. When it comes to parts that require tight tolerances and intricate shapes, the versatility and precision of a CNC grinding machine, especially a CNC roller ring grinding machine, make it the go-to solution. Whether it's for automotive components, aerospace parts, or high-precision tooling, the ability to create geometrically complex features on materials like steel, ceramics, or alloys has opened new possibilities for manufacturers.

One of the most impressive capabilities of CNC grinding machines is their ability to perform multiple types of grinding in a single setup, allowing for the creation of various complex geometries. For example, a CNC roll ring grinder can perform external cylindrical grinding, internal grinding, and even surface grinding in one continuous operation. This multi-functionality eliminates the need for several machines, reducing setup time, improving efficiency, and ensuring that all aspects of a workpiece are processed with the same level of precision. The seamless integration of these grinding functions is a key factor in the versatility and adaptability of the machine.

At the heart of achieving complex geometries is the highly precise control system that a CNC grinding machine uses. With automated digital controls, operators can program complex profiles and geometries, ensuring the grinding process follows the exact specifications every time. The CNC system allows for real-time monitoring and fine adjustments during the grinding process, ensuring that the workpieces meet the required dimensions and surface finishes. This level of control is particularly crucial for industries that demand high accuracy and consistency, such as the production of high-end automotive components or intricate tooling.

Additionally, CNC grinding machines like the CNC roller ring grinding machine offer significant flexibility when it comes to material choices. The ability to grind materials such as hardened steel, ceramics, and specialized alloys gives manufacturers the freedom to experiment with different designs without worrying about machine limitations. This versatility is particularly beneficial in industries where materials with challenging hardness or toughness are frequently used, such as aerospace or medical device manufacturing.

The key to CNC grinding's success in achieving complex geometries lies in the precision of its grinding tools. These machines utilize high-quality grinding wheels and abrasives, which are selected based on the material being processed and the specific geometry being created. The grinding tools themselves are customizable, allowing for specific designs that can meet the exact needs of the project. For example, a CNC grinding machine can be equipped with diamond or CBN (cubic boron nitride) wheels for tough materials, ensuring the machine can handle even the most challenging manufacturing tasks.

Another notable advantage of CNC grinding machines is their efficiency in production. Once set up, these machines can operate continuously, creating high volumes of complex parts with little intervention. This efficiency makes them ideal for mass production in industries like automotive and electronics, where consistent quality and high throughput are essential. By reducing manual labor and increasing automation, CNC grinding machines also lower the risk of human error, which is particularly important when working with tight tolerances.

Finally, the benefits of CNC grinding machines extend beyond just the machining process itself. Manufacturers using CNC grinding equipment, such as the CNC roll ring grinder, experience increased overall productivity, improved product quality, and reduced waste. By using a precise and automated process, companies can reduce scrap rates and ensure that every part is produced to the exact specification required. This contributes to both cost savings and higher customer satisfaction, making CNC grinding a critical investment for any business focused on quality and precision.

In conclusion, CNC grinding machines, particularly the CNC roller ring grinding machine, are indispensable in the modern manufacturing world for creating complex geometries with high precision. Their ability to perform multiple types of grinding operations, combined with advanced control systems and customizable tooling, allows manufacturers to achieve the intricate and precise designs that are in demand across industries. As manufacturers continue to push the boundaries of what's possible, CNC grinding machines will remain at the forefront of technological innovation, ensuring that high-quality, complex parts can be produced efficiently and reliably.

English

English  русский

русский  Español

Español  عربى

عربى

View More

View More View More

View More View More

View More