Understanding the Role of Precision in Grinding Wheel Dressing for Improved Tool Performance and Longevity

In the world of precision machining, the process of dressing grinding wheels is critical for maintaining optimal performance. Whether you are working with diamond wheels or cubic boron nitride (CBN) wheels, a Diamond Wheel Dressing Machine plays an essential role in ensuring that your tools continue to operate at their highest potential. Dressing the grinding wheel involves reshaping its surface to restore the cutting efficiency and geometry, a process that requires precision to avoid compromising the wheel’s performance. In industries where high-precision parts are the norm, such as aerospace or mold-making, the role of a Diamond Wheel Dressing Grinder cannot be overstated.

The precision of the dressing process directly impacts the surface finish of the workpiece and the overall efficiency of the grinding operation. By using a Diamond Wheel Dressing Machine, manufacturers can ensure that their grinding wheels maintain the sharpness and geometry necessary for precise material removal. This improves not only the quality of the finished product but also the lifespan of the grinding wheel itself. Without proper dressing, grinding wheels can quickly wear out or develop uneven surfaces that lead to subpar performance and increased downtime in production.

One of the main reasons for dressing a grinding wheel is to remove the layer of worn-out abrasive material that forms on the surface. When this layer is left unaddressed, it can cause the grinding wheel to lose its cutting ability and generate excessive heat, which in turn can damage both the workpiece and the grinding machine. By regularly using a Diamond Wheel Dressing Grinder, you ensure that the wheel remains sharp and that its geometry is preserved, allowing for efficient grinding with minimal heat buildup and wear.

Another benefit of precision dressing is the reduction in material wastage. In high-precision industries, even the slightest deviation in the grinding wheel’s geometry can lead to poor surface finishes and faulty parts. A well-dressed grinding wheel maintains a consistent cutting edge that helps reduce defects and material waste, improving both productivity and cost efficiency. The Diamond Wheel Dressing Machine ensures that every grinding operation is executed with the necessary accuracy, leading to better results and fewer rejected parts in the production process.

In addition to improving the grinding wheel’s performance, precision dressing also extends the life of the grinding wheel. By maintaining the correct wheel shape and sharpness, the dressing process reduces the frequency with which wheels need to be replaced. This, in turn, lowers operating costs for manufacturers. The Diamond Wheel Dressing Machine is designed with this in mind, ensuring that the dressing process is efficient, consistent, and tailored to the specific needs of the grinding wheel.

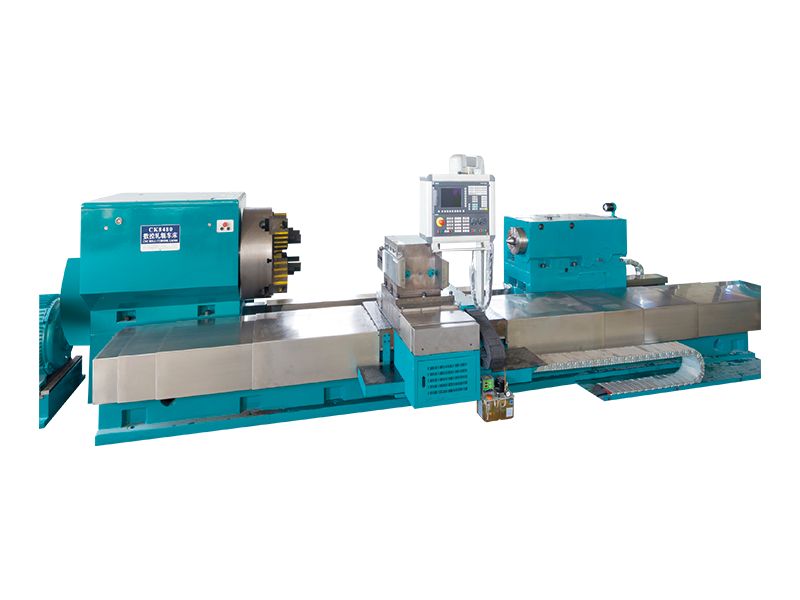

Moreover, with advancements in CNC systems and automation, modern Diamond Wheel Dressing Machines have made it easier than ever to achieve the precise results required for high-end manufacturing. These machines offer superior control over the dressing process, reducing human error and enhancing repeatability. Operators can rely on automated settings to achieve consistent wheel geometry, which is critical when producing complex parts that require tight tolerances. This level of precision is especially valuable in industries like optics, where even the smallest deviation can cause a product to fail.

In conclusion, the precision provided by a Diamond Wheel Dressing Grinder is indispensable for industries that rely on high-quality grinding operations. By ensuring that grinding wheels remain sharp, geometrically correct, and capable of maintaining optimal performance, manufacturers can improve not only the efficiency of their operations but also the quality and consistency of their finished products. As technology continues to evolve, the role of Diamond Wheel Dressing Machines in ensuring high-precision manufacturing will only grow more critical, making them a must-have tool for businesses looking to stay competitive in today’s demanding market.

English

English  русский

русский  Español

Español  عربى

عربى

View More

View More View More

View More