CNC Roll Lathe effectively improves the efficiency and accuracy of metal forming processing

In the rapidly evolving manufacturing landscape, the demand for precision and efficiency in metal forming processes has never been higher. The need for advanced machinery to enhance productivity and ensure high-quality output is crucial. One such innovation that has revolutionized metalworking industries, particularly in the steel sector, is the CNC (Computer Numerical Control) Roll Lathe. These specialized machines have proven to be essential in improving both the efficiency and accuracy of metal forming processing.

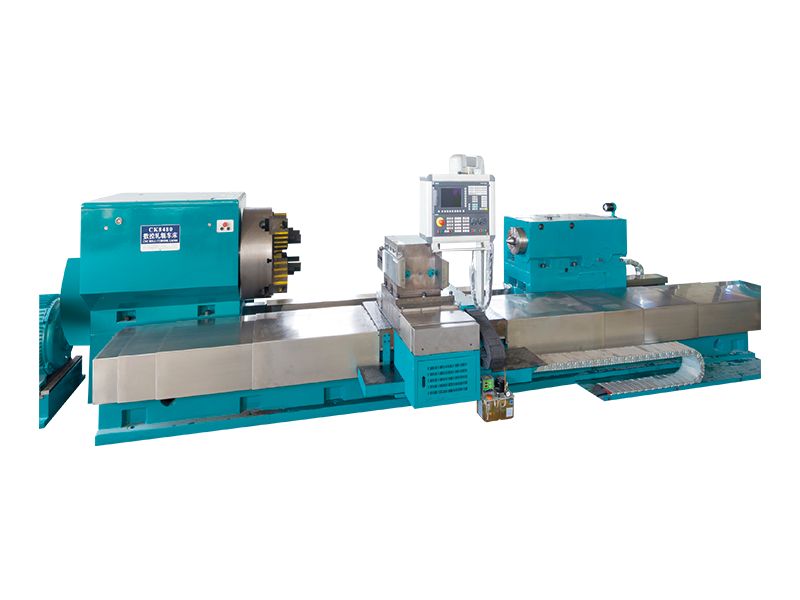

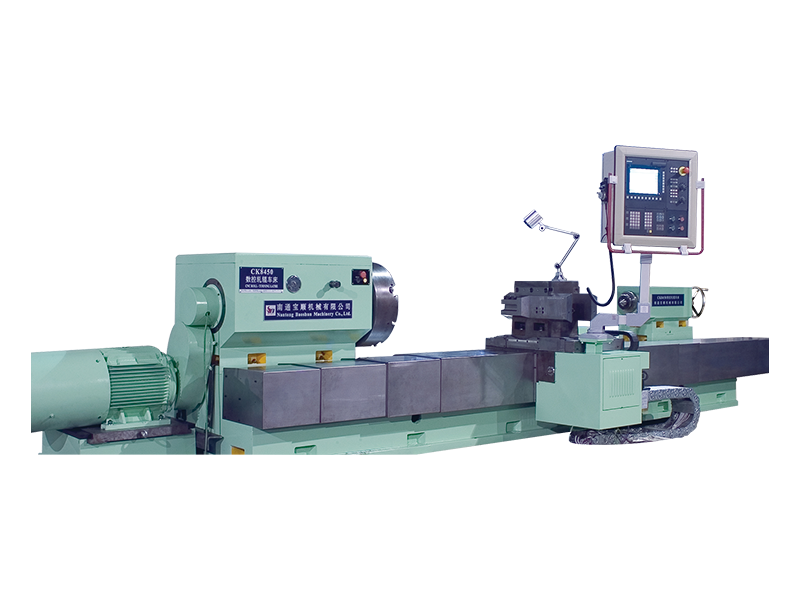

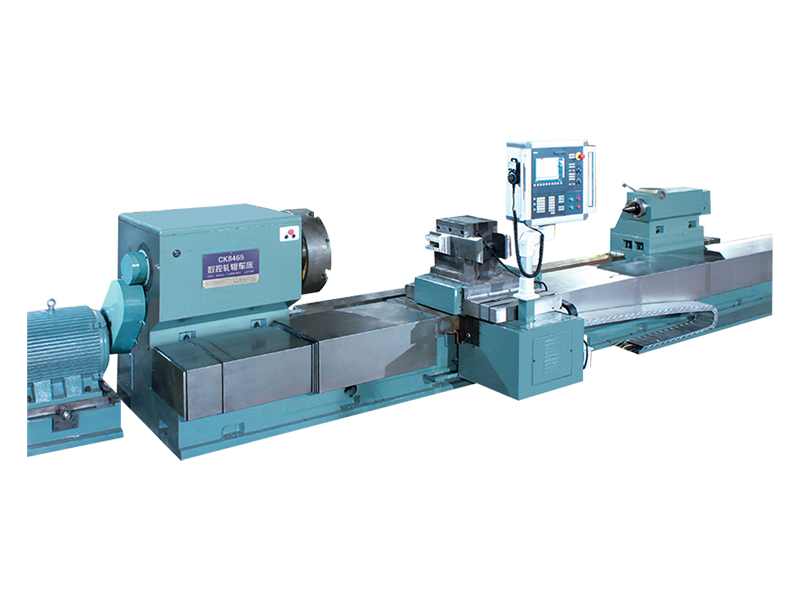

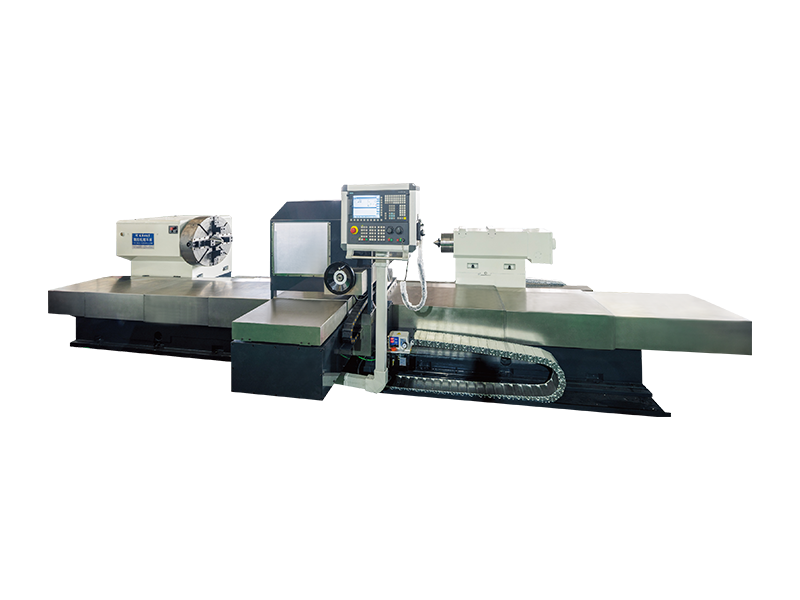

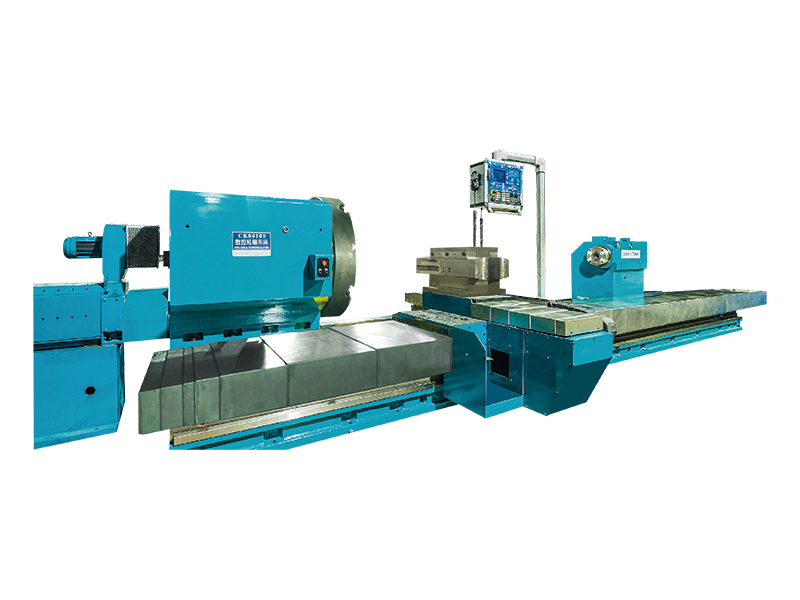

Jiangsu Dingshun Heavy Duty Machine Tool Co., Ltd., a renowned enterprise founded in 2002, has made significant contributions to the development and supply of machine tool equipment, especially for the metallurgical and steel industries. With a solid foundation and over two decades of expertise, the company specializes in manufacturing a range of CNC roll lathes, including their flagship products, the CK84 series CNC roll lathes. These machines are engineered to meet the demanding requirements of modern metalworking, offering a high level of precision and operational efficiency.

Precision and Efficiency in CNC Roll Lathes

CNC Machines for Rolling Mills, such as those produced by Jiangsu Dingshun, play a critical role in the manufacturing of rolls used in steel mills and other metal forming processes. These lathes are capable of performing a variety of complex tasks, such as turning, milling, and grinding, with unmatched precision. This versatility allows for the creation of highly accurate metal components, which is essential for industries where tight tolerances and surface finishes are critical.

The CK84 series CNC Roll Notching Machine are designed with cutting-edge technology that integrates advanced automation and control systems. These features significantly improve the consistency and accuracy of the final product. By utilizing CNC technology, the machines can execute repetitive tasks with high precision, reducing the chances of human error and increasing throughput. This not only leads to better quality products but also reduces material waste, making the process more cost-effective.

Enhancing Production Efficiency

One of the most notable advantages of CNC Roll Notching Machine for Rolling Mills is their ability to drastically improve production efficiency. In traditional machine tools, operators are required to manually set up and adjust machines for each specific task, which can be time-consuming and prone to errors. However, with CNC roll lathes, the setup process is automated, and once the program is set, the machine can run with minimal supervision.

This automation allows for faster turnaround times, increased production rates, and the ability to run machines continuously. Jiangsu Dingshun’s CNC roll lathes, like the CA84 series digital display roll lathes and the CXK9550 CNC turning and milling composite machine tools, are capable of performing multiple operations in a single setup. This reduces downtime and ensures a smoother workflow, which is crucial for industries that require high-volume production.

Additionally, these machines are equipped with advanced diagnostic tools that provide real-time monitoring of machine performance. This not only enhances operational efficiency but also helps in early detection of any potential issues, allowing for quick maintenance and reducing unexpected downtime. By increasing the reliability and longevity of the equipment, companies can ensure sustained high productivity.

Meeting the Demands of Modern Steel Industries

The metallurgical and steel industries require machinery that can handle the rigorous demands of large-scale metal forming. CNC roll lathes are particularly essential in these environments as they are designed to handle the precise shaping of metal rolls, which are used in rolling mills for shaping steel and other metals. The precision and repeatability offered by CNC machines make them an ideal solution for industries that need high-quality and dimensionally accurate rolls.

Jiangsu Dingshun has established itself as a trusted supplier of solutions for steel enterprises. Their CNC roll lathes and other products are widely used in various industrial applications, from roll ring grinders (such as the MK630 CNC vertical roll ring grinder) to precision universal grinding machines (such as the ZWM150). Their reputation for producing high-quality, reliable machine tools has earned them the distinction of being a qualified supplier for prestigious organizations like the Shanghai 704 Research Institute of China Shipbuilding Industry Corporation.

The introduction of CNC roll lathes, such as those produced by Jiangsu Dingshun Heavy Duty Machine Tool Co., Ltd., has significantly transformed the metal forming industry. These machines offer unparalleled precision, efficiency, and versatility, ensuring that metal components are produced to the highest standards of quality. By improving both accuracy and production efficiency, CNC roll lathes are indispensable tools for modern manufacturing, especially in the metallurgical and steel industries. With the continued advancement of CNC technology, the future of metal forming processing looks even more promising, paving the way for enhanced productivity and innovative manufacturing solutions.

English

English  русский

русский  Español

Español  عربى

عربى

View More

View More View More

View More View More

View More View More

View More View More

View More