How CNC Pattern Milling Machines Improve Efficiency and Accuracy in Manufacturing

CNC (Computer Numerical Control) pattern milling machines have revolutionized the manufacturing industry by enabling high-precision processing of complex patterns on a wide range of materials. This advanced equipment is particularly beneficial in industries such as construction, decoration, and mold manufacturing, where precision and efficiency are paramount. By incorporating CNC technology, these machines ensure consistent machining quality, reduce human error, and significantly improve overall production efficiency.

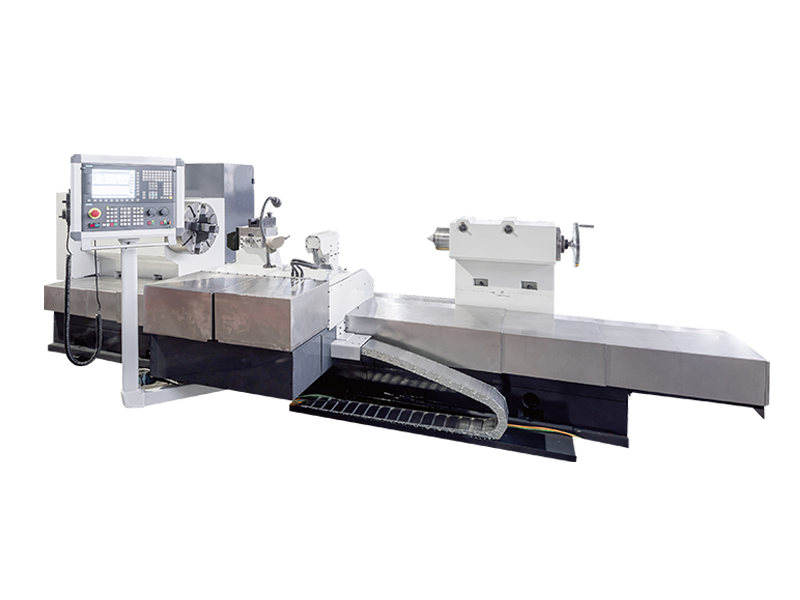

At the heart of this transformation is the machine's ability to automate complex milling processes. CNC pattern milling machines can process a variety of patterns with high precision, including flat milling, inclined surface milling, and contour milling. This versatility makes them suitable for various materials like aluminum alloys, copper, and plastics, allowing manufacturers to meet diverse production requirements. The ability to program the machine using CNC systems further enhances production efficiency by eliminating the need for manual intervention, which results in faster turnaround times and greater consistency across production runs.

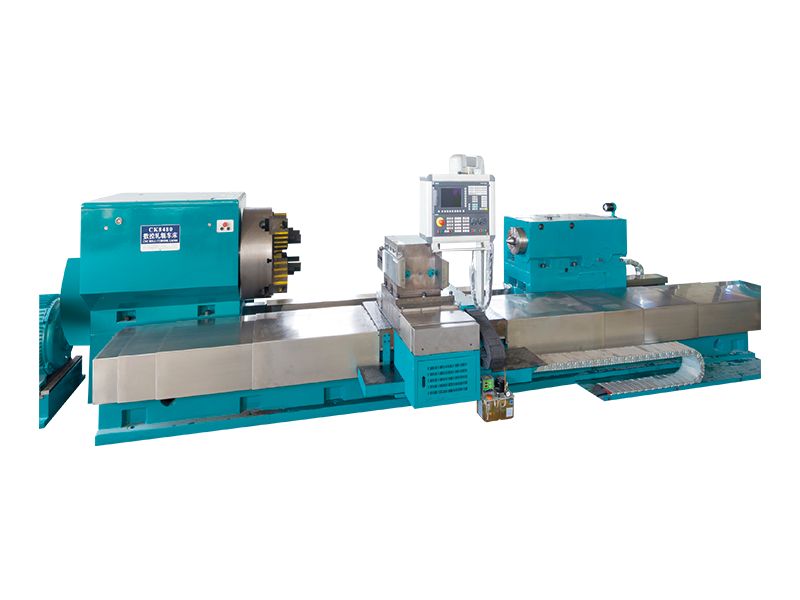

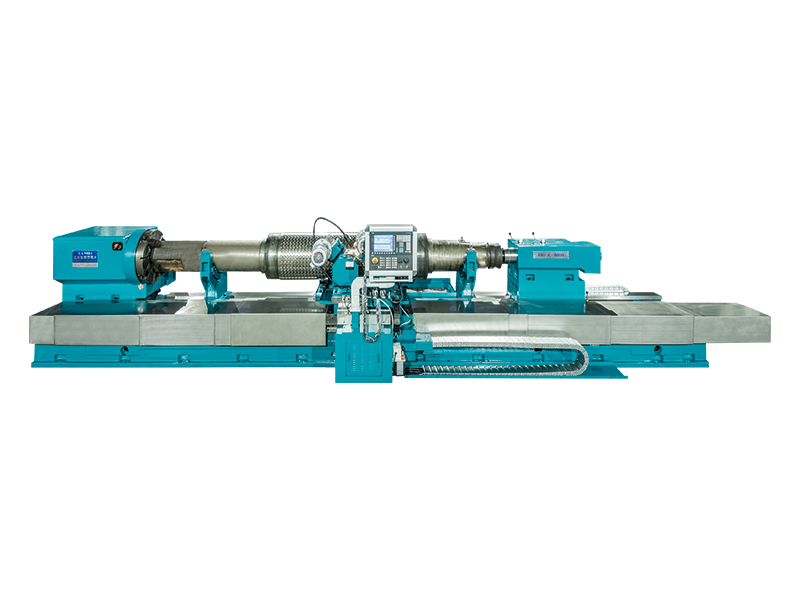

Jiangsu Dingshun Heavy Duty Machine Tool Co., Ltd., a company specializing in advanced machine tools for the metallurgical industry, exemplifies the benefits of CNC technology in manufacturing. Established in 2002, the company has built a strong reputation for producing high-quality CNC equipment, including the XK500 series CNC roll crescent groove processing machines and CXK9580 patterned plate CNC turning and milling centers. With extensive experience and a strong technical foundation, the company continues to develop innovative solutions that enhance production processes for industries like steel manufacturing, while ensuring the efficiency and accuracy of their products.

One of the key advantages of CNC pattern milling machines is their ability to handle complex and detailed patterns with remarkable precision. This capability is particularly important in industries that require highly detailed parts, such as mold manufacturing. The integration of digital display systems in CNC pattern milling machines allows operators to monitor the processing status in real-time, ensuring that adjustments can be made quickly to maintain optimal machining conditions. This continuous monitoring system reduces the risk of errors and helps maintain high-quality standards throughout production.

In addition to precision, CNC pattern milling machines contribute to greater efficiency through features such as automatic tool changing. This function minimizes downtime by automatically switching between tools based on the programmed instructions, further streamlining the manufacturing process. With these capabilities, CNC pattern milling machines are ideal for mass production environments, where high volume and consistency are critical.

Jiangsu Dingshun Heavy Duty Machine Tool Co., Ltd. understands the importance of maintaining high operational efficiency and product quality. The company has invested heavily in advanced equipment and technology, ensuring their products meet the rigorous demands of the manufacturing industry. Through their dedication to innovation and technological advancement, they have earned multiple national patents and independent intellectual property rights, solidifying their position as a trusted supplier for steel enterprises and metallurgical industries.

Regular maintenance and upkeep are also essential for the long-term reliability of CNC pattern milling machines. By ensuring that these machines are consistently maintained, manufacturers can avoid unexpected downtime and costly repairs. In turn, this contributes to the overall efficiency of production lines, allowing companies to meet tight deadlines and customer demands while maintaining high standards of quality.

CNC pattern milling machines play a crucial role in improving both the efficiency and accuracy of manufacturing processes. By automating complex tasks, reducing human error, and offering unmatched precision, these machines have become an indispensable tool in modern production environments. Companies like Jiangsu Dingshun Heavy Duty Machine Tool Co., Ltd. continue to innovate and provide solutions that enhance the capabilities of CNC pattern milling machines, driving advancements in industries such as steel manufacturing, construction, and mold making. With their strong focus on technological innovation and customer satisfaction, CNC pattern milling machines will remain a cornerstone of efficient and precise manufacturing for years to come.

English

English  русский

русский  Español

Español  عربى

عربى

View More

View More View More

View More