CNC Roll Processing Machines: A Key Component in Mass Production of High-Quality Rolls

The Importance of Precision in Roll Manufacturing

Rolls are essential components in numerous industrial processes, serving as vital parts in machines used for molding, forming, and pressing materials. For industries such as metallurgy, plastics, and textiles, producing these rolls with high precision is critical to achieving quality end products. This is where the CNC roll processing machine excels. Equipped with an advanced CNC system, the machine allows for complex programming and fine adjustments, ensuring high levels of accuracy in every step of the roll production process.

From carbon steel to stainless steel and various alloys, the CNC roll processing machine offers the flexibility to process different materials with high precision. The multi-functional nature of the machine allows it to handle complex roll shapes and sizes, offering versatility in the kinds of rolls it can produce. Whether it’s turning, milling, or grinding, the machine delivers consistent and reliable results, making it an invaluable asset in modern manufacturing.

Enhancing Efficiency and Productivity

One of the standout features of CNC roll processing machines is their ability to automate various aspects of the machining process. Automation improves both productivity and safety, significantly reducing manual intervention and human error. Features such as automatic tool changing and clamping functions streamline the production process, allowing for more efficient processing of rolls, even in high-volume operations.

These automated processes, combined with the digital display system that continuously monitors operational parameters, ensure that the machine operates at optimal levels. Operators can make real-time adjustments, maximizing the efficiency and safety of the machine, thereby increasing the throughput of quality rolls in less time. This capability is especially crucial for industries involved in mass production, where meeting tight production deadlines without compromising quality is essential.

The Role of Jiangsu Dingshun in CNC Roll Processing Machine Innovation

As a leading player in the CNC roll processing machine market, Jiangsu Dingshun Heavy Duty Machine Tool Co., Ltd. (also known as Nantong Baoshun Machinery Co., Ltd.) has established a reputation for providing state-of-the-art equipment to meet the needs of steel enterprises and metallurgical industries. Founded in 2002, the company has extensive experience in designing and manufacturing specialized machine tool equipment, particularly CNC roll processing machines.

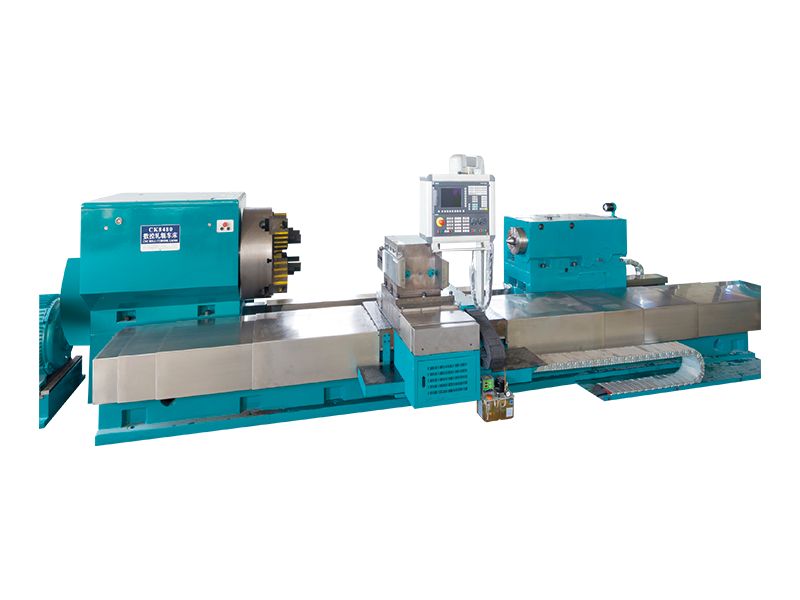

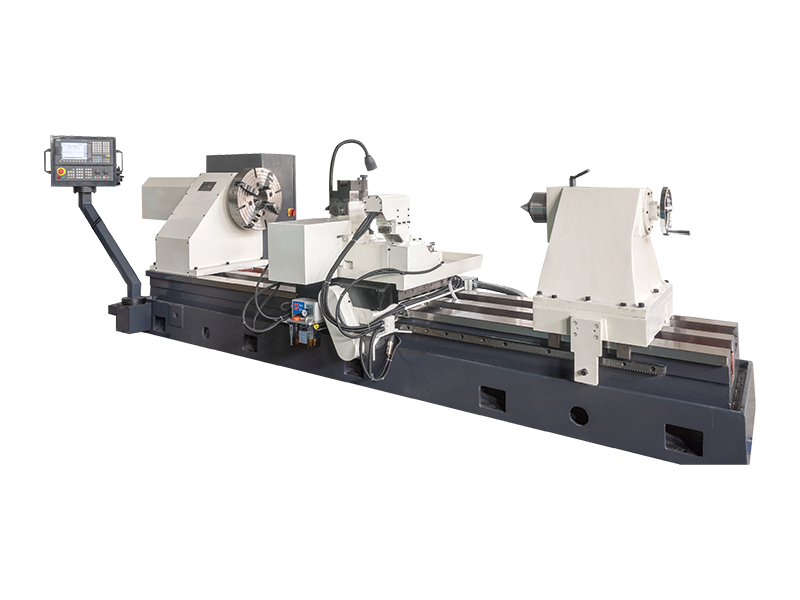

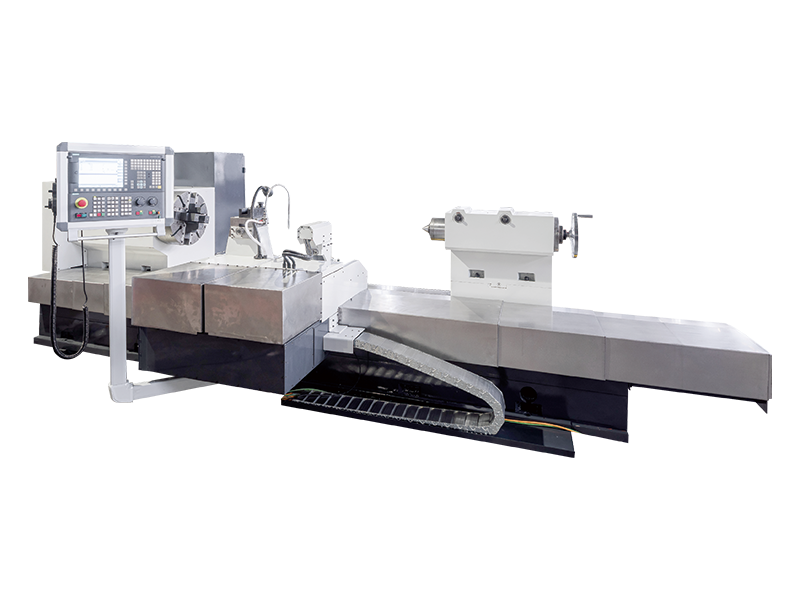

Jiangsu Dingshun’s product lineup includes the XK500 series CNC roll crescent groove processing machine tools, the CK84 series CNC roll lathes, and the CXK9550 CNC turning and milling composite machine tools. These machines are designed with cutting-edge technology to meet the diverse requirements of roll manufacturing and repair. The company’s commitment to technological innovation, backed by years of expertise, ensures that their CNC roll processing machines offer unparalleled precision and reliability for mass production.

Moreover, the company’s strong technical foundation and mature product line allow it to cater to the specific needs of steel companies and metallurgical enterprises. Jiangsu Dingshun’s products are widely used across the industry and have earned positive customer feedback from both domestic and international markets. The company’s dedication to quality is reflected in its acquisition of multiple national patents and independent intellectual property rights, which further solidify its leadership in the field of roll processing technology.

The Future of CNC Roll Processing Machines in Mass Production

As industries continue to push for higher production standards and quality, CNC roll processing machines are becoming more sophisticated. Advanced features such as real-time monitoring systems, thermal protection, and overload sensors ensure the long-term stability of these machines, even in the face of demanding production environments. With these innovations, CNC roll processing machines not only meet current industry needs but also lay the foundation for future advancements in roll manufacturing.

Jiangsu Dingshun’s ongoing commitment to technological research and industry-university cooperation further strengthens its position as a leader in the CNC roll processing machine market. By focusing on continuous product innovation and service excellence, the company is poised to meet the growing demands of the steel and metallurgical industries, playing a crucial role in advancing the development of China’s steel production and ensuring the global competitiveness of its machinery.

The CNC roll processing machine is undeniably a key component in the mass production of high-quality rolls. Its ability to process a wide range of materials with extreme precision, along with its efficiency-enhancing features such as automation and real-time monitoring, makes it an invaluable tool in industries that require precision-engineered rolls. Companies like Jiangsu Dingshun continue to innovate and improve CNC roll processing technologies, ensuring that they meet the evolving needs of the global manufacturing landscape. With such advancements, the future of roll production looks more efficient, precise, and adaptable than ever before.

English

English  русский

русский  Español

Español  عربى

عربى

View More

View More View More

View More