Content

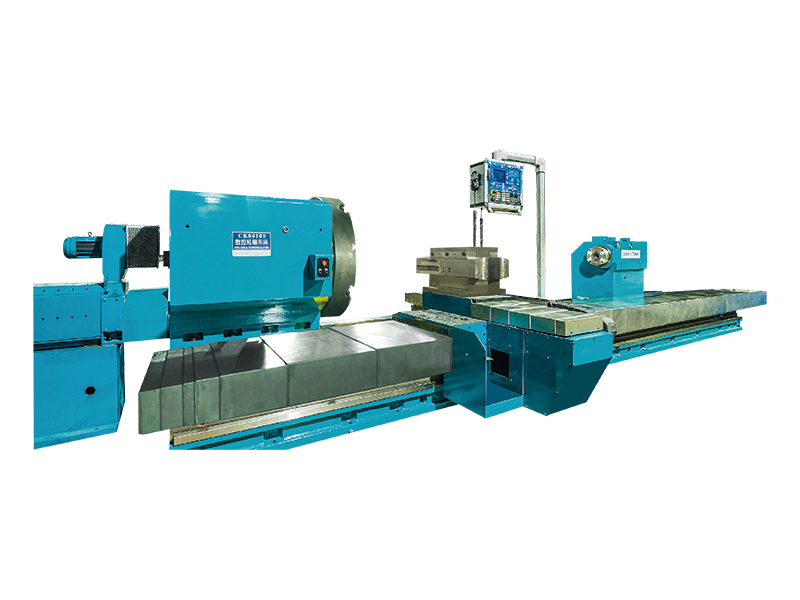

Heavy-duty CNC roll lathes are specialized machine tools designed for precision machining of large rolls used in industries such as steel, paper, aluminum, and plastics. These lathes are engineered to provide accurate diameter control, high-quality surface finishing, and reliable performance for rolls of various sizes and materials. The integration of computer numerical control (CNC) allows operators to achieve consistent precision while reducing manual intervention and operational errors.

Understanding the components of a heavy-duty CNC roll lathe is essential to appreciate its capabilities in achieving precise diameter and surface finishes. Each part contributes to stability, accuracy, and ease of operation.

The lathe bed and frame provide structural support, minimizing vibrations during machining. Heavy-duty cast iron or welded steel constructions enhance rigidity, which is critical for maintaining consistent tolerances and achieving superior surface finishes on large rolls.

The spindle rotates the roll, while the chuck securely holds it in place. High-precision spindles with robust bearings enable smooth rotation and accurate concentricity, which is vital for diameter control. Hydraulic or mechanical chuck systems ensure stability and reduce roll movement during machining.

A CNC-controlled tool turret allows automatic selection and movement of cutting tools. Operators can program precise cutting paths, feed rates, and depth of cut, resulting in consistent surface quality and dimensional accuracy. Advanced CNC systems also include real-time monitoring and error correction for improved precision.

Heavy-duty CNC roll lathes are widely used in industries where large rolls require high precision and smooth surface finishes. Their versatility makes them suitable for both production and maintenance tasks.

In rolling mills, CNC roll lathes machine work rolls, backup rolls, and other components with strict tolerances. Precise diameter control ensures uniform material thickness, while high-quality surface finishes reduce friction and wear during the rolling process.

CNC roll lathes are used to machine calender rolls, press rolls, and dryer rolls in paper production. Accurate surface finishing enhances sheet quality, reduces paper defects, and improves operational efficiency.

In plastic and film industries, precision-machined rolls are essential for controlling thickness, surface texture, and coating uniformity. Heavy-duty CNC lathes enable precise grinding and turning, ensuring consistent material quality and reducing waste.

Heavy-duty CNC roll lathes offer several advantages over conventional manual or semi-automatic lathes, improving productivity and reducing errors in industrial applications.

Selecting the right CNC roll lathe requires evaluating factors such as roll size, material, machining accuracy, and production requirements. Proper selection ensures optimal performance and durability.

| Feature | Consideration | Recommendation |

| Max Roll Diameter | Size of rolls to be machined | Select lathe with sufficient swing over bed and spindle capacity |

| Spindle Power | Material hardness and cutting speed | High-torque spindle recommended for heavy steel or cast rolls |

| CNC Control Accuracy | Tolerance and finish requirements | Choose advanced CNC with fine resolution and error compensation |

| Tooling System | Type of cutting and grinding operations | Multi-axis tool turret or grinding system for versatility |

Heavy-duty CNC roll lathes are essential for industries requiring precise diameter control and high-quality surface finishing on large rolls. Their combination of structural rigidity, advanced CNC control, and versatile tooling enables manufacturers to achieve consistent, efficient, and cost-effective production. Proper selection and operation of these lathes maximize performance, reduce material waste, and ensure optimal roll quality for steel, paper, aluminum, and other industrial applications.