Tool grinding is a critical process in manufacturing, directly affecting the performance, lifespan, and accuracy of cutting tools used in machining operations. The choice between CNC (Computer Numerical Control) tool grinders and conventional manual tool grinders significantly impacts precision, efficiency, and overall production quality. Understanding the key differences helps manufacturers select the right equipment for their operational needs.

Content

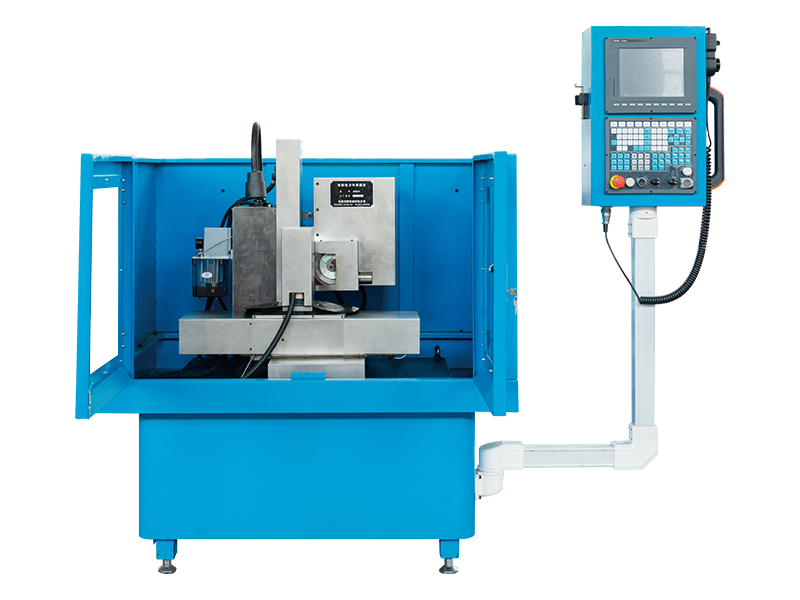

CNC tool grinders are designed for high-precision operations. By utilizing computer-controlled movements and pre-programmed tool geometries, CNC grinders can achieve micron-level tolerances consistently. They maintain the exact angles, radii, and profiles required for modern cutting tools such as end mills, drills, and reamers.

In contrast, manual tool grinders rely on the operator’s skill and experience to shape the tool. While skilled operators can produce accurate tools, achieving consistent high-precision results across multiple tools is challenging. Manual grinding introduces variability due to human factors, such as slight differences in hand positioning, pressure, or timing, which can affect tool performance and repeatability.

Efficiency is another significant difference between CNC and manual grinding:

CNC grinders automate the grinding process, reducing setup times and operator intervention. Once a tool profile is programmed, the machine can produce multiple tools in sequence with minimal adjustments, significantly increasing throughput. This automation also enables batch production of complex or custom tools, which would be time-consuming on manual grinders.

Manual grinders require continuous attention from the operator. Each tool must be carefully aligned, ground, and inspected, making the process slower and labor-intensive. Complex geometries may require multiple setups and adjustments, further reducing efficiency compared to CNC machines.

CNC tool grinders excel in handling complex tool geometries that are difficult or impossible to replicate manually. Features such as 5-axis grinding, automatic wheel compensation, and software-controlled feed rates allow CNC machines to create intricate tool profiles with consistent quality.

Manual grinders, while versatile for basic sharpening and simple tool shapes, struggle with multi-faceted or high-precision tools. Achieving complex angles and profiles often requires multiple grinding wheels, specialized jigs, and significant operator expertise.

One of the strongest advantages of CNC grinding is repeatability. Once a tool program is set, the machine can reproduce identical tools dozens or hundreds of times without deviation. This consistency ensures that all tools perform predictably in production, minimizing variability in machining operations.

Manual grinding, in contrast, is prone to minor inconsistencies between tools, even when performed by an experienced operator. These small deviations can impact cutting performance, tool life, and the quality of machined parts.

While CNC tool grinders offer superior precision and efficiency, they require a higher initial investment and technical training for operators. The software interface, machine calibration, and maintenance procedures necessitate specialized knowledge.

Manual grinders have a lower upfront cost and simpler operation, making them suitable for small workshops, low-volume tool maintenance, or situations where budgets are constrained. However, the long-term cost of labor, slower production, and potential tool inconsistencies can offset the initial savings.

In summary, the key differences between CNC and conventional manual tool grinders in terms of precision and efficiency are:

For manufacturers seeking high precision, repeatability, and efficiency—especially in industrial or high-volume tool production—CNC tool grinders are the optimal choice. Manual grinders remain valuable for small workshops, maintenance tasks, or simpler tool shapes where speed and automation are less critical.