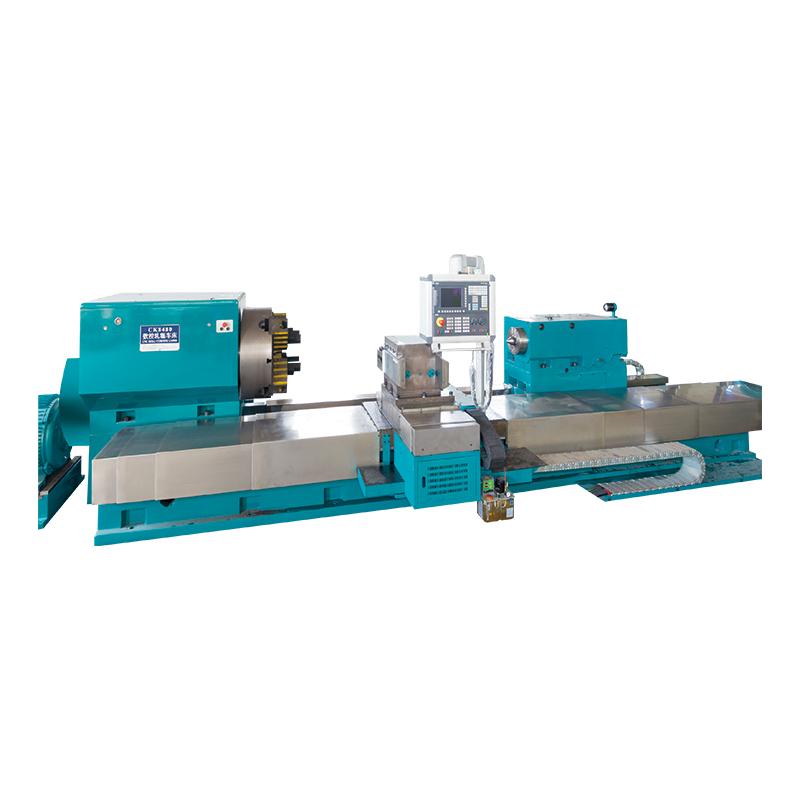

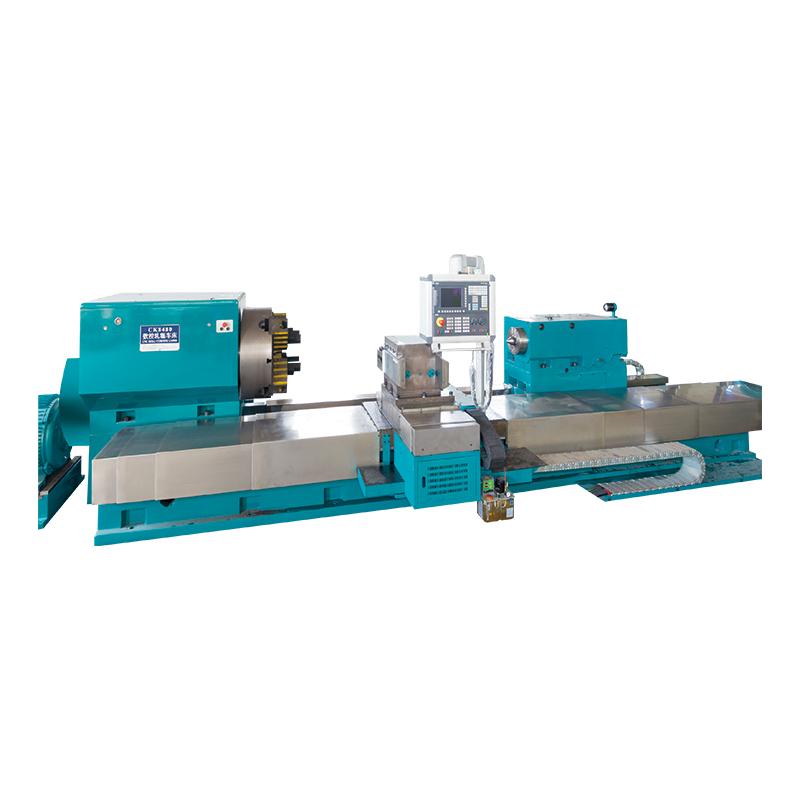

Pattern plate milling machines are highly specialized tools used in industries that demand accuracy, repeatability, and surface integrity. Unlike general-purpose milling machines, these machines are optimized for pattern plates, mold bases, and structural components where dimensional stability and fine surface finish are essential. However, the performance of such a machine does not only depend on its design or operator skill—it is also deeply influenced by the compatibility of the material being processed.

Every material interacts with the cutting tool and spindle differently. Harder materials may increase tool wear, softer ones may lead to burr formation, and composites may require dust management. Selecting the right material is therefore just as important as programming the right toolpath. In this article, we will explore in depth the wide variety of materials that can be effectively milled using pattern plate milling machines, analyzing their characteristics, applications, and challenges.

1. Metals: The Backbone of Milling Applications

Metals are among the most common materials processed on pattern plate milling machines. They are valued for their mechanical strength, durability, and versatility.

1.1 Steel

Steel is one of the most frequently milled materials. Pattern plate milling machines can handle different grades, from mild steel to hardened tool steel.

- Advantages: High strength, availability, cost-effectiveness.

- Challenges: Hardened steel requires high spindle power, specialized carbide tools, and proper cooling to prevent thermal deformation.

- Applications: Mold bases, machine frames, heavy-duty pattern plates.

1.2 Aluminum

Aluminum is lightweight and highly machinable. It is often chosen when weight reduction is important without sacrificing too much strength.

- Advantages: Excellent machinability, fast cutting speeds, good thermal conductivity.

- Challenges: Tendency to form built-up edge on tools; requires sharp cutters and lubrication.

- Applications: Aerospace plates, automotive components, electronics housings.

1.3 Brass & Copper

Both brass and copper are softer metals but widely used for precision parts.

- Advantages: Easy to machine, excellent surface finish, corrosion resistance.

- Challenges: Copper’s ductility may lead to smearing; brass is more forgiving but requires sharp tooling.

- Applications: Electrical connectors, decorative elements, heat exchangers.

1.4 Stainless Steel

Stainless steel is valued for its corrosion resistance and strength.

- Advantages: Strong, durable, highly resistant to rust.

- Challenges: Work hardening, high cutting forces, potential heat buildup.

- Applications: Food-grade equipment plates, marine applications, medical instruments.

1.5 Titanium

Titanium combines strength and lightness, making it crucial in aerospace and medical industries.

- Advantages: High strength-to-weight ratio, excellent corrosion resistance.

- Challenges: Low thermal conductivity causes heat concentration at the cutting edge; requires specialized coatings and rigid setups.

- Applications: Aircraft plates, surgical instruments, high-performance components.

1.6 Cast Iron

Cast iron is another traditional material for pattern plates.

- Advantages: Good wear resistance, excellent damping capacity.

- Challenges: Brittleness, dust generation during milling.

- Applications: Engine blocks, machine bases, molds.

2. Plastics and Polymers: Lightweight and Versatile

Polymers are increasingly used in modern engineering due to their flexibility, low weight, and resistance to corrosion. Pattern plate milling machines can process several types effectively.

2.1 Nylon (PA)

Nylon is widely used for gears, bushings, and wear-resistant components.

- Pros: Good machinability, low friction.

- Cons: Moisture absorption may cause dimensional instability.

2.2 Polyacetal (POM/Delrin)

POM is a high-performance engineering plastic known for stability and machinability.

- Pros: Dimensional stability, smooth finish, low friction.

- Cons: Limited resistance to very high temperatures.

2.3 Acrylic (PMMA)

Commonly used for transparent parts.

- Pros: Clear optical quality, aesthetic appeal.

- Cons: Brittle, prone to cracking if mishandled.

2.4 Polycarbonate (PC)

Stronger than acrylic, with impact resistance.

- Pros: High strength, good clarity.

- Cons: More difficult to machine cleanly without stress cracking.

2.5 PTFE (Teflon)

PTFE is chemically resistant and has low friction.

- Pros: Non-stick properties, chemical resistance.

- Cons: Softness leads to challenges in holding tolerances.

2.6 Polyethylene (PE) and Polypropylene (PP)

Common for lightweight, low-cost components.

- Pros: Easy to process, inexpensive.

- Cons: Limited strength, lower temperature resistance.

3. Composites: Strength with Reduced Weight

Composite materials combine fibers with resins to achieve strength without excessive weight.

3.1 Carbon Fiber Reinforced Polymer (CFRP)

- Advantages: High stiffness, lightweight.

- Challenges: Abrasive fibers cause tool wear; requires diamond-coated tools.

- Applications: Aerospace panels, automotive sports components.

3.2 Fiberglass (GFRP)

- Advantages: Cost-effective, good strength.

- Challenges: Similar tool wear issues as carbon fiber.

- Applications: Marine structures, industrial panels.

3.3 Hybrid Composites

These combine different fibers for specialized performance.

- Applications: High-end engineering structures requiring both toughness and lightness.

4. Wood and Engineered Materials

Although not the primary focus for pattern plate milling, certain industries use these machines for wood-based materials.

- Hardwood: Durable, stable, but variable grain may affect finish.

- Plywood and MDF: Uniform, easier to machine, but produce dust requiring extraction.

- Applications: Prototyping, pattern models, furniture.

5. Advanced and Specialty Materials

Some specialized industries require milling of unconventional materials.

- Ceramics: Requires specialized diamond tooling.

- Laminates: Used in electronics and decorative industries.

- High-temperature alloys: For aerospace and defense applications.

6. Tooling and Machine Requirements

To process such diverse materials, tooling must be adapted:

- Cutters: Carbide, diamond-coated, or high-speed steel depending on material.

- Cooling: Essential for metals to reduce heat; some plastics require air instead of liquid cooling.

- Feeds & Speeds: Optimized per material to balance tool life and finish.

7. Real-World Applications Across Industries

- Aerospace: Titanium, CFRP, aluminum plates.

- Automotive: Steel, aluminum, plastics.

- Electronics: Copper, POM, acrylic.

- Energy: Stainless steel, composites.

- Medical: Titanium, stainless steel, PEEK.

8. Challenges in Milling Different Materials

- Heat buildup in metals.

- Tool wear in composites.

- Dimensional instability in plastics.

- Dust generation in wood and cast iron.

9. Future Trends in Material Compatibility

- Hybrid materials with embedded sensors.

- AI-driven adaptive milling adjusting speeds automatically.

- Eco-friendly materials replacing traditional plastics.

- Improved coatings for longer tool life.

Conclusion: Matching Material to Machine Capability

Pattern plate milling machines are versatile enough to process metals, plastics, composites, and specialty materials. Each comes with its unique characteristics that influence tool choice, cooling methods, and cutting parameters. For engineers and manufacturers, the key is to match the material’s properties with the machine’s capability to achieve optimal results. With advances in tooling and machine technology, the scope of materials compatible with these machines will only continue to expand, ensuring their place as indispensable tools in modern manufacturing.