Content

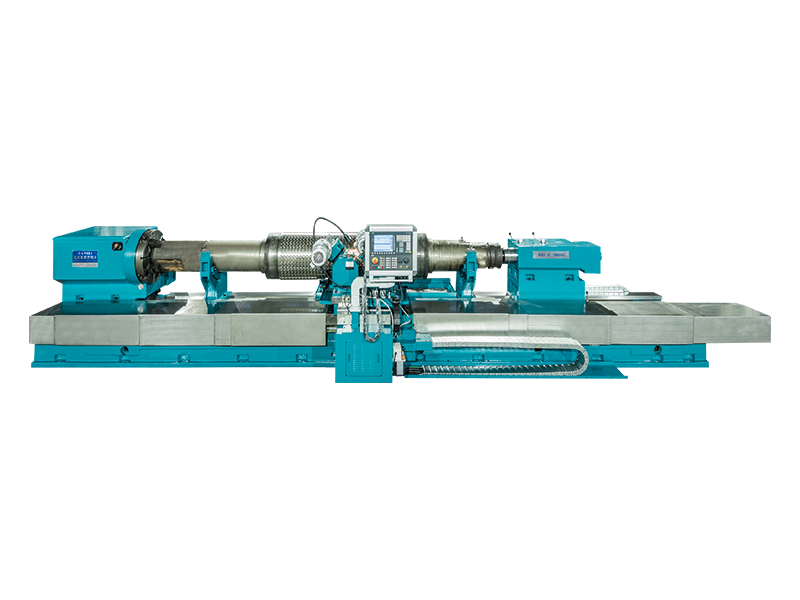

CNC machines have become an integral part of modern rolling mill operations, offering enhanced automation, precision, and process control. By replacing manual or semi-automated systems, CNC technology allows rolling mills to achieve higher product consistency, improved efficiency, and reduced operational errors. Integration of CNC systems streamlines production from raw material processing to finished products while maintaining tight tolerances.

Automation through CNC machines minimizes human intervention in critical rolling processes. Automated control of roll positioning, speed, and tension reduces variability and ensures uniform material thickness. CNC systems also allow pre-programming of rolling schedules for different product types, eliminating manual adjustments and speeding up production changeovers.

Automation improves safety by reducing operator exposure to high-temperature materials and moving machinery. In addition, real-time monitoring of rolling parameters helps detect anomalies early, preventing equipment damage or product defects.

CNC machines offer precise process control through advanced sensors, feedback loops, and software algorithms. Parameters such as roll gap, material tension, and temperature can be monitored continuously and adjusted in real time. This ensures that the final products meet strict dimensional and surface quality requirements.

Integrated control systems also allow synchronization of multiple rolling mill stands, enabling complex operations such as tandem rolling or variable thickness profiles. The ability to maintain uniformity across all stages of production enhances product reliability and reduces material waste.

CNC rolling mill machines can be integrated with broader production management systems such as SCADA or MES. This integration enables centralized monitoring, data logging, and performance analysis across multiple production lines. Operators and engineers can access real-time data on equipment status, material consumption, and production output to make informed operational decisions.

By connecting CNC machines to digital dashboards, rolling mills can implement predictive maintenance strategies, reduce downtime, and optimize production schedules.

Key performance metrics in CNC-integrated rolling mills include throughput rate, dimensional accuracy, energy consumption, and scrap reduction. Monitoring these metrics allows continuous process optimization. For example, adjustments to roll speed or tension can be made automatically based on material behavior to maintain consistent quality.

The table below summarizes how CNC features impact rolling mill performance:

| CNC Feature | Operational Benefit | Performance Impact |

| Automated Roll Gap Control | Consistent strip thickness | Reduced scrap and rework |

| Tension Monitoring and Adjustment | Uniform material flow | Improved surface quality |

| Temperature Feedback Control | Optimal rolling conditions | Enhanced dimensional accuracy |

| Multi-Stand Synchronization | Coordinated rolling operations | Efficient production of complex profiles |

While CNC integration offers operational advantages, proper maintenance is crucial for reliability. Regular calibration of sensors, inspection of actuators, and software updates ensure that the rolling mill continues to operate at peak performance. Predictive maintenance enabled by CNC data reduces unplanned downtime and extends the service life of critical components.

Routine preventive maintenance programs and trained operators familiar with CNC systems further enhance the reliability and longevity of rolling mill operations.

Integrating CNC machines into rolling mills provides significant benefits in automation, process control, and overall efficiency. By enabling precise control over rolling parameters, synchronizing multi-stand operations, and connecting to production management systems, CNC technology ensures consistent product quality, operational safety, and optimized performance. Properly maintained CNC rolling mills represent a strategic investment for manufacturers seeking to enhance productivity and competitiveness.