Content

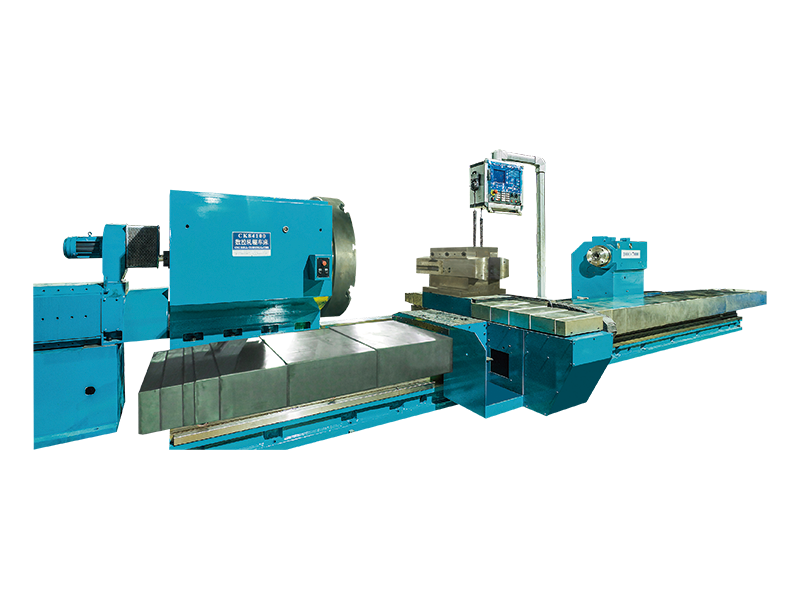

CNC roll notching machines are specialized equipment used to create precise notches, grooves, or reliefs on rolls used in various industrial processes. These rolls are commonly applied in material handling systems, forming lines, conveying equipment, and manufacturing processes that require accurate positioning or traction. Selecting the right CNC roll notching machine directly affects machining accuracy, production efficiency, and long-term operational stability.

Before choosing a CNC roll notching machine, it is necessary to clearly define your production needs. This includes understanding the types of rolls being processed, required notch geometry, and expected output volume. Machines designed for light-duty rolls may not meet the demands of high-load industrial applications.

Roll diameter, length, and material composition influence machine selection. CNC roll notching machines must support the maximum roll dimensions used in production while maintaining rigidity. Materials such as carbon steel, alloy steel, or coated rolls require stable cutting performance and appropriate spindle power to achieve clean and consistent notches.

For applications where roll alignment and engagement are critical, notching accuracy becomes a key factor. CNC-controlled systems provide precise positioning and repeatability, reducing dimensional variation across batches. This is particularly important in automated production lines where roll interchangeability is required.

Modern CNC roll notching machines offer a range of features that improve productivity and machining consistency. Understanding which features are essential helps avoid unnecessary complexity while meeting operational demands.

A reliable CNC control system allows operators to program notch positions, depths, and spacing with high precision. User-friendly interfaces reduce setup time and minimize programming errors. Compatibility with commonly used CNC standards simplifies integration into existing workshops.

Spindle performance affects cutting quality and tool life. Adequate spindle power ensures smooth material removal, especially when machining harder roll materials. Stable spindle operation reduces vibration, which directly contributes to better surface finish and dimensional consistency.

Secure and adaptable clamping systems are essential for roll notching operations. Proper fixtures prevent roll movement during machining, ensuring consistent notch geometry. Adjustable clamping designs allow quick changeover between different roll sizes, improving overall production efficiency.

Different CNC roll notching machine configurations are available to suit various production environments. The table below outlines common configurations and their typical applications.

| Machine Configuration | Primary Characteristics | Suitable Applications |

|---|---|---|

| Single-Station CNC Notching Machine | Simple structure, focused notching operation | Small to medium batch production |

| Multi-Axis CNC Notching Machine | Flexible tool movement, complex notch patterns | High-precision or custom roll designs |

| Automated CNC Notching Line | Integrated loading, machining, and unloading | High-volume continuous production |

Beyond machining performance, long-term operational efficiency depends on maintenance accessibility and system reliability. Machines with modular components and clear maintenance points reduce downtime and simplify routine servicing.

Choosing a CNC roll notching machine should align with both current production requirements and future expansion plans. Machines with scalable configurations or optional automation features allow manufacturers to adapt to changing order volumes and product variations without replacing core equipment.

Selecting the right CNC roll notching machine involves balancing precision requirements, production capacity, and operational efficiency. By carefully evaluating roll specifications, machine features, and long-term production objectives, manufacturers can invest in equipment that supports stable output, consistent quality, and sustainable growth across industrial applications.