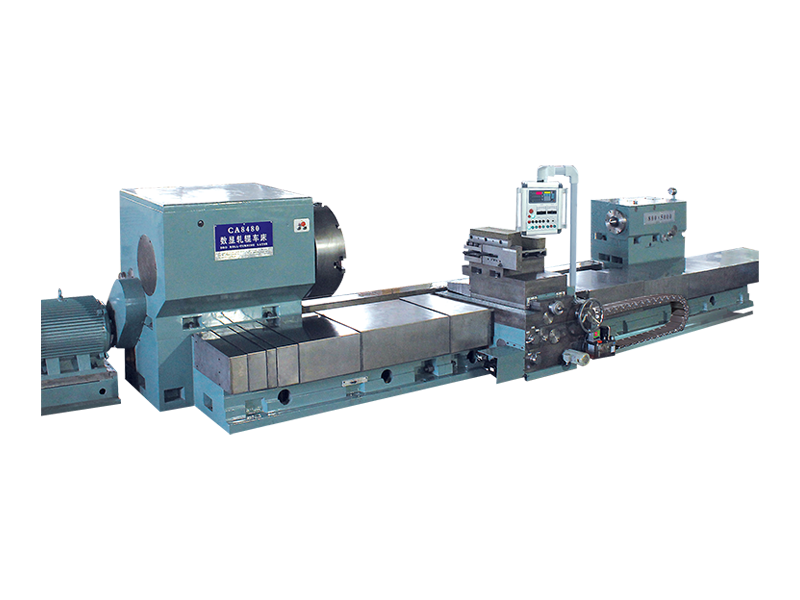

The digital display roll lathe is a revolutionary piece of equipment, offering unprecedented precision and efficiency in the manufacturing sector. This high-tech tool integrates advanced digital technologies to streamline the process of roll machining, delivering superior results for a range of industries. The machine’s ability to manage complex specifications and ensure consistent output has made it an indispensable asset in various fields. Here’s a closer look at the industries that stand to gain the most from incorporating a digital display roll lathe into their production processes.

Metalworking and Manufacturing

In metalworking, precision is paramount, and the digital display roll lathe rises to the occasion. This sector, which deals with the production of intricate parts and components, can benefit from the lathe’s accuracy and versatility. The machine’s digital interface allows operators to adjust settings with ease, ensuring each roll is crafted to exact specifications. Whether it's turning metal rollers, shafts, or cylindrical components, the digital display roll lathe ensures the highest standards of quality and consistency, minimizing human error and optimizing efficiency.

Paper and Pulp Industry

The paper and pulp industry demands equipment that can handle large-scale, high-speed production while maintaining tight tolerances. The digital display roll lathe’s ability to monitor and adjust parameters in real-time provides a distinct advantage here. Rollers used in paper mills are often subjected to intense wear and tear, and the precision offered by the digital lathe guarantees a longer lifespan and superior performance of these rollers. Furthermore, the enhanced monitoring capabilities allow for predictive maintenance, which minimizes downtime and boosts overall productivity.

Textile and Fabric Manufacturing

Textile manufacturers are another group that can significantly benefit from digital display roll lathes. The consistent quality of the rolls is crucial for textile production, as any imperfections can lead to costly delays and defects in the fabric. Digital lathes enable precise shaping of rollers used in processes such as weaving, knitting, and dyeing. With real-time adjustments and high precision, the digital lathe ensures that fabric production is not only faster but also of a higher quality.

Printing Industry

In the printing industry, the roll lathe is used to create rollers that are vital for ink application, paper handling, and other critical operations. The digital display roll lathe enhances the production of these rollers, offering more consistent surface finishes and better tolerance control. Its ability to fine-tune adjustments ensures that printing rollers remain in optimal condition for longer, improving print quality and reducing waste. As the digital lathe eliminates manual errors, it also speeds up the manufacturing process, resulting in a more efficient and cost-effective operation.

Rubber and Plastic Processing

The rubber and plastic industries often require precision rollers for extrusion and molding processes. The digital display roll lathe can significantly enhance the quality of these rollers by maintaining tighter tolerances and more uniform shapes. Whether producing rubber rollers for automotive applications or plastic rollers for packaging, the digital lathe ensures that each roll is manufactured to exact standards, reducing defects and improving the final product's performance. The system's digital capabilities also allow for faster adjustments, making it ideal for industries with high production demands.

Food Processing and Packaging

In food processing, machinery that handles food products must adhere to strict hygiene and operational standards. The digital display roll lathe plays a key role in ensuring that rollers used in packaging lines are manufactured with precision and cleanliness. These rollers, which are integral to conveyor belts and packaging machinery, require high tolerance to function smoothly. The digital lathe guarantees these standards by providing consistent, repeatable results that meet both regulatory and operational demands. By increasing the precision of the rollers, manufacturers can reduce waste and ensure that food products are handled and packaged efficiently and hygienically.

Automotive Industry

The automotive industry is another major sector that can gain from the use of a digital display roll lathe. Rollers are used in numerous applications, from coating and finishing parts to producing high-precision components for vehicles. The digital lathe's ability to provide fine-tuned control over the dimensions and surface finish of automotive parts ensures better quality, fewer defects, and reduced wastage. Additionally, its fast operational speeds and enhanced accuracy help meet the high-volume demands of automotive production.

Aerospace and Aviation

Aerospace and aviation manufacturing demands the highest levels of precision, particularly in the creation of parts that must withstand extreme conditions. The digital display roll lathe’s capabilities in achieving high tolerance and surface finish make it an invaluable tool for this sector. Rollers used in the production of aerospace components, such as turbine blades and structural elements, benefit from the digital lathe’s ability to maintain tight specifications while reducing material waste. The system's digital interface also allows for rapid reprogramming, making it well-suited to the fast-paced demands of aerospace production.

From metalworking and textile manufacturing to the automotive and aerospace industries, the digital display roll lathe is transforming production processes. Its precision, efficiency, and ease of use make it an indispensable tool across various sectors. As industries continue to prioritize automation, precision, and operational efficiency, the digital lathe stands as a cornerstone of modern manufacturing, ensuring that businesses can meet growing demands while maintaining top-tier quality standards.