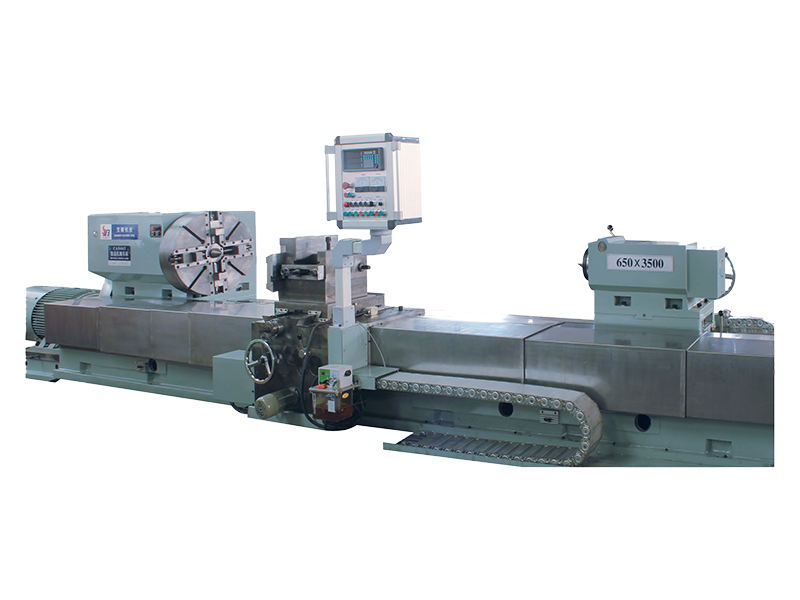

In today’s rapidly evolving manufacturing landscape, the demand for precision and efficiency has never been greater. Industries ranging from aerospace to automotive are increasingly relying on advanced machinery to meet the exacting standards of modern production. Among these innovations, the Digital Display Roll Lathe (DDRL) stands out as a formidable contender for high-precision machining tasks. But is it truly capable of delivering the level of accuracy required for such demanding applications?

The DDRL, with its integrated digital display technology, brings a new level of sophistication to machining. By offering real-time, highly accurate readings, it ensures that operators can make fine adjustments with unparalleled precision. The result is an enhancement in both the quality and consistency of machined components, which are crucial in industries where even minute deviations can result in costly defects or failures.

One of the primary advantages of the DDRL lies in its ability to provide real-time feedback. Unlike traditional manual lathes, which rely heavily on human judgment and the potential for error, the DDRL offers instant readings on key metrics such as rotational speed, cutting depth, and tool positioning. This constant stream of data allows operators to make immediate adjustments, ensuring that the machining process remains on track and within the stringent tolerances required for high-precision tasks.

Moreover, the advanced digital interface of the DDRL significantly reduces the likelihood of operator errors. By displaying clear, concise measurements, it minimizes the cognitive load on operators, allowing them to focus entirely on the task at hand. In industries where precision is paramount, the ability to work with such detailed feedback not only enhances productivity but also leads to a reduction in material waste and rework costs.

However, while the DDRL excels in many areas, it is important to understand its limitations. The digital display technology, while revolutionary, can be susceptible to certain environmental factors, such as extreme temperatures or electromagnetic interference. In these situations, the precision of the system may be compromised, necessitating additional safeguards or recalibrations to ensure that performance remains at optimal levels. This is particularly relevant in environments where consistency is critical, such as in the production of aerospace components or medical devices.

Additionally, the effectiveness of the DDRL can depend on the complexity of the machining task at hand. While the system is highly effective for tasks requiring moderate to high precision, extremely intricate operations may still require specialized equipment or supplementary technology to achieve the desired results. In cases where ultra-precise, nano-level tolerances are required, other advanced machining solutions, such as precision CNC machines, may be better suited to the task.

The Digital Display Roll Lathe is indeed a valuable tool for high-precision machining, particularly in industries where consistent quality and operational efficiency are crucial. Its ability to deliver real-time, accurate data significantly enhances the machining process, providing a competitive edge in modern manufacturing. However, its suitability for the most complex and ultra-precise applications remains contingent on the specific requirements of the task and the operating environment. For many applications, the DDRL represents a highly effective and efficient choice, but for others, additional technology may be necessary to achieve the ultimate level of precision.