Content

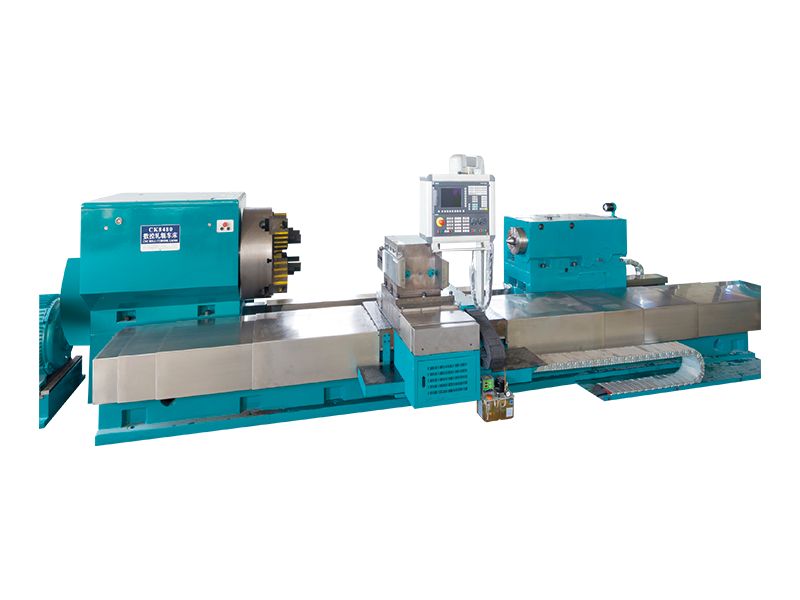

CNC roll ring grinders are engineered to deliver extremely precise grinding of roll rings, which are critical components in various industrial applications such as steel mills and metal forming equipment. By leveraging computer numerical control, these grinders achieve micron-level tolerances, ensuring each roll ring meets strict dimensional and geometric requirements. The automated control eliminates inconsistencies commonly found in manual grinding, resulting in superior surface finish and consistent accuracy across production batches.

The surface finish of a roll ring directly impacts its performance in rolling processes. CNC roll ring grinders enhance surface quality through:

These methods reduce micro-cracks, surface roughness, and dimensional deviation, which enhances the overall lifespan of the roll rings and the quality of the final rolled products.

CNC roll ring grinders rely on advanced control systems to achieve unparalleled accuracy. Features include:

This level of control eliminates human error and allows manufacturers to produce roll rings with exact dimensions, concentricity, and roundness, which are critical for high-performance rolling operations.

Different roll ring materials, such as hardened steel, cast iron, and alloyed metals, respond differently to grinding processes. CNC roll ring grinders allow operators to adjust parameters based on material hardness and thermal sensitivity, ensuring optimal surface finish and dimensional accuracy without causing microstructural damage. For example:

| Material | Recommended Grinding Approach |

| Hardened Steel | High-speed fine-grit grinding with controlled coolant flow |

| Cast Iron | Moderate-speed grinding with abrasive wheel dressing for uniform surface |

| Alloyed Metals | Custom feed rates and pass schedules to avoid surface burn and cracking |

CNC roll ring grinders not only enhance surface finish and accuracy but also improve overall productivity. By automating the grinding process:

This combination of precision and efficiency ensures that manufacturers meet tight production schedules while maintaining high-quality standards.

CNC roll ring grinders play a critical role in achieving exceptional surface finish and dimensional accuracy for roll rings used in demanding industrial applications. By integrating advanced CNC control, optimized grinding techniques, and material-specific approaches, these grinders deliver consistent, high-quality results that improve product performance and extend component lifespan. Their automation capabilities also enhance productivity and reduce operational variability, making CNC roll ring grinders an indispensable tool in modern manufacturing environments.