The world of manufacturing has undergone a massive transformation with the introduction of CNC technology, and nowhere is its impact more evident than in the development of the CNC pattern milling machine. These machines have revolutionized industries by offering unprecedented precision, speed, and flexibility. In this article, we will explore how CNC technology powers modern milling machines, the benefits it brings to manufacturing processes, and how it improves the overall quality of output.

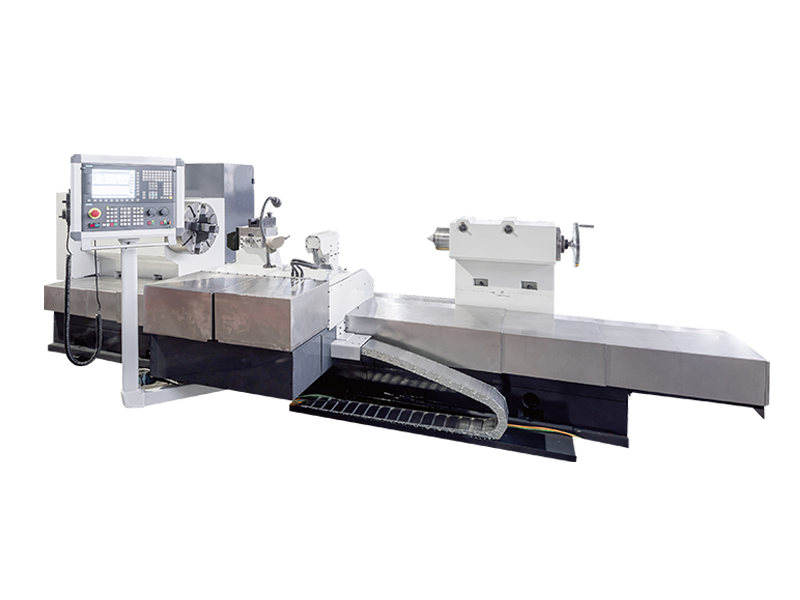

CNC, or Computer Numerical Control, involves the use of computers to control machining tools, such as drills, lathes, and mills. The CNC pattern milling machine is a perfect example of how this technology has elevated manufacturing. Unlike traditional manual milling, where the operator must control the machine’s movements by hand, a CNC system automates this process. The result is more consistent and accurate patterns, making it ideal for industries like construction, mold making, and decorative surfaces.

One of the key advantages of CNC pattern milling is its ability to handle complex designs that would be impossible or highly time-consuming with manual methods. The machine can execute intricate patterns with exceptional accuracy, which is especially critical in fields like decorative milling where the smallest imperfection can affect the final product. With CNC technology, manufacturers can produce consistent and high-quality patterns on various materials, including aluminum, copper, and plastics.

Incorporating CNC technology into milling machines has also drastically reduced human error. Programming the machine to follow precise instructions ensures that every part is made according to the design specifications, without the variations that can occur due to manual control. This precision makes CNC pattern milling machines indispensable in high-volume production, where consistency is crucial. Operators can focus on monitoring the process rather than making constant adjustments, boosting overall productivity and efficiency.

Moreover, the efficiency of CNC pattern milling machines extends beyond precision. These machines often come equipped with automated tool changers, which allow for seamless switching between different tools without manual intervention. This functionality dramatically reduces downtime between operations and increases the overall speed of production. In industries where time is money, this improvement in efficiency can result in significant cost savings and faster turnaround times.

The flexibility of CNC milling machines is another noteworthy advantage. Manufacturers can easily modify the designs or switch between different milling tasks, such as flat milling, contour milling, and inclined surface milling, with minimal effort. This versatility makes CNC pattern milling machines ideal for diverse applications, from small-scale custom projects to large-scale production runs. The ability to switch tools and processes without interrupting production makes these machines an excellent choice for companies looking to streamline their operations.

For manufacturers, investing in a CNC pattern milling machine is more than just a technical upgrade; it's a step towards future-proofing their business. The continued advancements in CNC technology promise even greater improvements in automation, machine learning, and artificial intelligence, opening doors for even higher levels of precision and efficiency. For those in industries requiring high-quality pattern production, embracing CNC milling technology is not just an option but a necessity for staying competitive in today’s fast-paced manufacturing environment.

In conclusion, the CNC pattern milling machine offers a level of precision, speed, and flexibility that was once unimaginable. By automating complex milling tasks, manufacturers can achieve consistent results with fewer mistakes, reduced labor costs, and faster production times. As industries continue to push the boundaries of what is possible in manufacturing, CNC pattern milling machines will remain at the forefront of this revolution, delivering exceptional value to businesses that require reliable, high-quality patterning solutions.