In the evolving landscape of modern manufacturing, the demand for high-precision, high-efficiency machining solutions continues to rise. Among the many specialized machine tools developed to meet this need, the CNC roller ring lathe stands out as a vital asset for the machining of large-scale bearing components, especially roller rings and slewing rings used in heavy industries such as wind energy, metallurgy, marine equipment, and mining.

This article provides an in-depth look at CNC roller ring lathes, including their structural features, functional advantages, and industrial significance.

Content

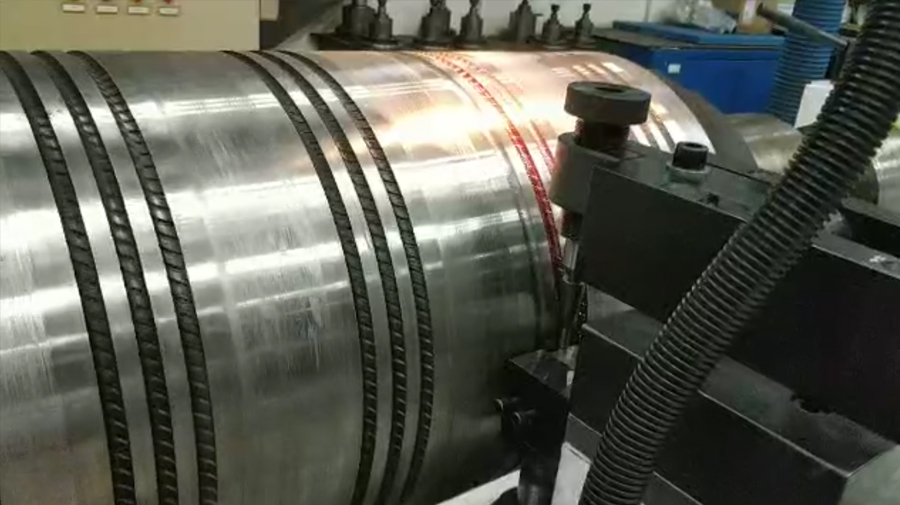

A CNC roller ring lathe is a numerically controlled turning machine designed specifically for machining circular workpieces with large diameters and ring-shaped geometries. These workpieces typically include slewing bearings, bearing rings, turntable rings, and other circular components that demand tight tolerances, smooth finishes, and uniform profiles.

Unlike standard CNC lathes, roller ring lathes are engineered to handle large-diameter, heavy-duty workpieces that require stable clamping, high torque, and multi-axis precision control.

A CNC roller ring lathe generally features the following main components:

Some advanced models also integrate live tooling, linear scales for feedback, and automated loading/unloading systems for enhanced productivity.

The CNC roller ring lathe is capable of performing a wide range of machining processes on large ring-shaped workpieces, including:

These machines can handle components with diameters ranging from a few hundred millimeters up to several meters, making them ideal for oversized and ultra-heavy applications.

CNC roller ring lathes are not general-purpose machines—they serve high-value industries that demand accuracy, reliability, and repeatability in ring-shaped components:

Used to machine yaw and pitch bearings in wind turbines, which must maintain precise dimensions under harsh outdoor conditions and constant movement.

Ring gears, bearing rings, and rotary kilns in steel mills and foundries rely on tightly toleranced parts manufactured with roller ring lathes.

Heavy-duty slewing bearings used in cranes, excavators, and tunnel boring machines are typically machined on CNC ring lathes to ensure structural integrity.

Large slewing rings and propulsion system components for vessels require circular turning solutions with high metal removal rates and robust rigidity.

Rotary joints, large thrust bearings, and sealing rings used in extractive industries are commonly machined using these lathes.

The superiority of roller ring lathes lies not just in their size-handling capability, but also in their technological advantages:

Advanced CNC control systems allow precise tool positioning and contour following, ensuring uniformity in internal and external diameters.

The rigid structure, optimized feed systems, and fine tool path control help achieve smooth, burr-free surfaces—even on tough alloys.

Programmable sequences, automatic tool change, and electronic feedback eliminate human error and reduce cycle times.

CNC roller ring lathes can be programmed to produce different ring sizes and profiles without extensive mechanical reconfiguration.

With automated controls and efficient material handling systems, operators are relieved from labor-intensive manual adjustments.

To achieve optimal machining outcomes, several factors should be evaluated when investing in or configuring a CNC roller ring lathe:

Additionally, service support, software updates, and spare parts availability should not be overlooked when sourcing from a supplier or manufacturer.

As Industry 4.0 continues to influence manufacturing processes, CNC roller ring lathes are evolving to support smart production environments:

These advancements position CNC roller ring lathes as not just heavy-duty turning machines, but critical enablers of digital and automated manufacturing ecosystems.

The CNC roller ring lathe is a cornerstone technology in the machining of large, circular, and high-precision components across demanding industries. By combining powerful structural capacity with modern CNC intelligence, these machines ensure both accuracy and efficiency in producing vital components like bearing rings, slewing rings, and gear blanks.

As industries continue to prioritize quality, precision, and productivity, the role of CNC roller ring lathes will become even more prominent. Whether for a new production line or to upgrade legacy equipment, investing in this category of advanced turning machinery is a strategic move toward robust and future-ready manufacturing.