Lathes are essential in metalworking and precision machining industries. Among the various lathe types available today, the CNC roller lathe and the traditional lathe stand out as fundamentally different in both operation and application. While both are used to shape rotating workpieces, they differ significantly in technology, automation level, precision, and the specific types of jobs they are designed for.

Content

A traditional lathe, often called a manual lathe, is a machine tool that rotates a workpiece on its axis to perform operations like cutting, sanding, drilling, or turning, using a cutting tool manually controlled by an operator.

Traditional lathes come in various types such as:

These machines are still commonly found in repair shops, maintenance workshops, and training institutions.

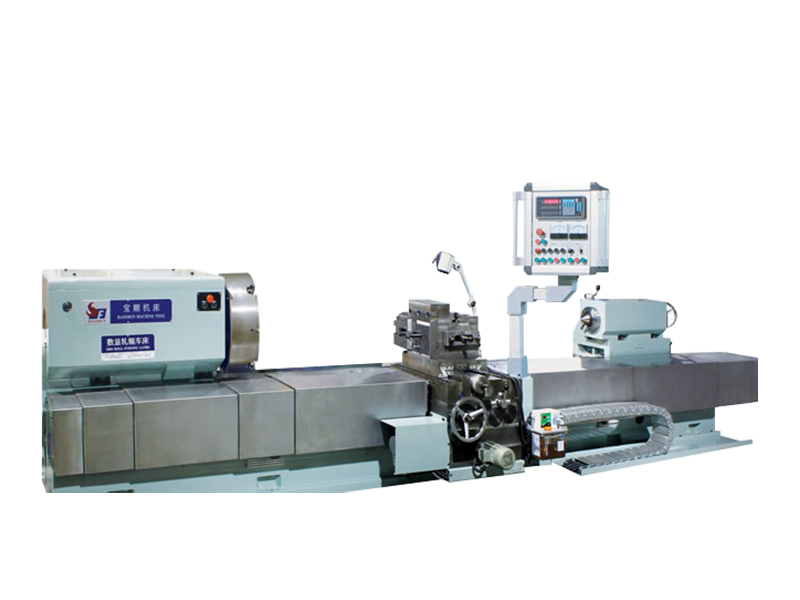

A CNC roller lathe is a specialized, computer-controlled lathe designed primarily for processing cylindrical rollers, such as those used in metallurgy, paper manufacturing, printing, and heavy industrial machinery. The CNC system precisely controls the cutting process, ensuring uniformity, high speed, and micron-level accuracy.

CNC roller lathes are often custom-built for industrial-scale roller manufacturing, capable of handling rollers weighing several tons and measuring several meters in length.

| Feature | Traditional Lathe | CNC Roller Lathe |

| Control System | Manual | Computer-controlled |

| Application Focus | General-purpose turning | Precision roller machining |

| Operator Requirement | Skilled operator required for every process | Minimal operator input needed |

| Production Volume | Small batch, repair work | High-volume, repeatable production |

| Machining Complexity | Limited to basic shapes | Complex profiles, crowning, tapering |

| Accuracy | Operator-dependent | Consistent, high-precision |

| Tool Handling | Manual tool changes | Automated tool turrets or changers |

| Setup Time | Shorter for single pieces | Longer initial setup but faster for mass production |

| Data Integration | None | Fully programmable, integrates with CAD/CAM software |

Precision and Consistency

CNC roller lathes achieve a level of precision that is difficult for manual lathes to match. They can maintain tolerances as tight as ±0.001 mm, which is crucial when producing industrial rollers with consistent performance.

Automation and Productivity

Once a machining program is created and loaded, a CNC lathe can run with minimal supervision, making it ideal for continuous production and large-scale manufacturing.

Complex Machining Capabilities

CNC roller lathes can perform complex geometries such as:

Reduced Human Error

Manual errors such as tool misalignment or inconsistent feed rates are eliminated, resulting in better quality control.

Integration with Digital Design

CNC lathes can directly interpret CAD files, making prototyping, testing, and scaling production faster and more efficient.

Despite the technological edge of CNC lathes, traditional lathes still have their place in the workshop. They are ideal when:

CNC roller lathes are specialized for industries that rely on high-quality, large-diameter rollers, including:

Each of these sectors requires high load-bearing capacity, surface finish quality, and dimensional accuracy, all of which CNC roller lathes are engineered to deliver.

With ongoing advancements in automation, AI integration, and digital manufacturing, even traditional lathes are being retrofitted with CNC systems or hybrid solutions. Smart factories increasingly rely on data-driven machining to reduce waste, cut costs, and boost throughput.

The key difference between a CNC roller lathe and a traditional lathe lies in their level of automation, intended use cases, and precision capabilities. While traditional lathes remain relevant for simpler, low-volume tasks, CNC roller lathes are indispensable for industries requiring heavy-duty, high-accuracy roller production on a large scale.

Choosing between the two depends on the nature of the work, budget, production volume, and required precision. For manufacturers involved in roller production or any process demanding high tolerance and consistency, the CNC roller lathe is clearly the superior choice.